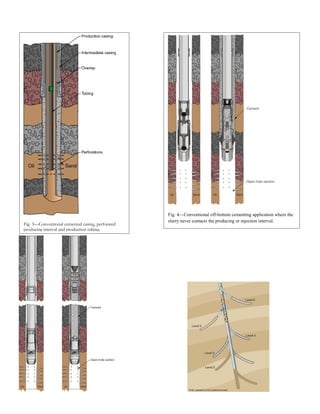

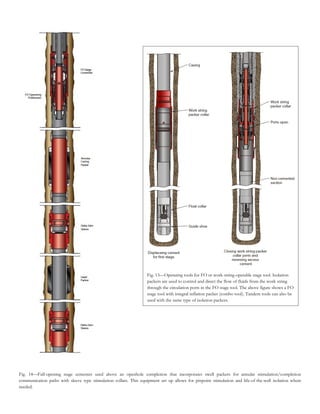

This document discusses off-bottom cementing techniques used in well construction. It describes how selective-release stage cementing equipment allows cementing sections of casing while avoiding contamination of production zones. Specifically, it allows the upper section of casing to be cemented without cement contacting lower, cement-sensitive zones. This technique uses diverting tools run with casing to divide cement into stages and achieve isolation. The document provides examples of how these methods are applied with liners, multilaterals and subsea completions.