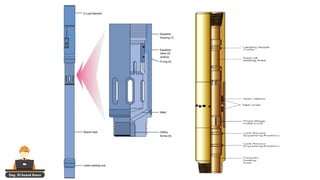

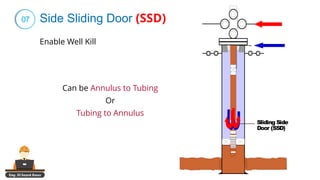

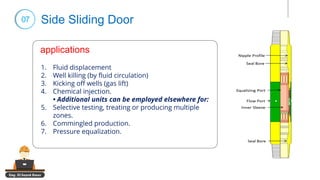

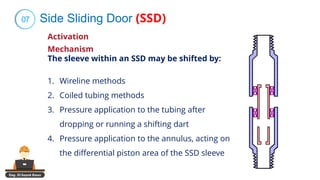

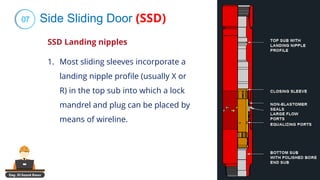

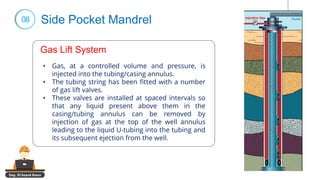

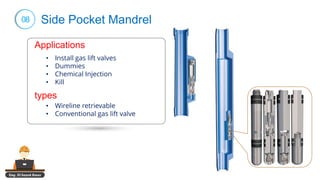

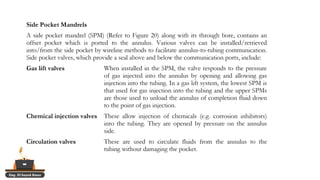

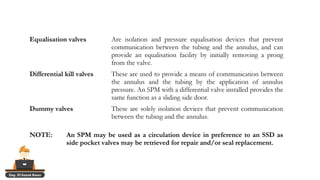

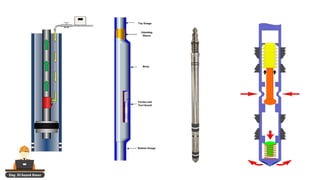

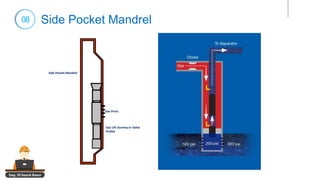

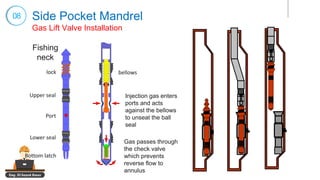

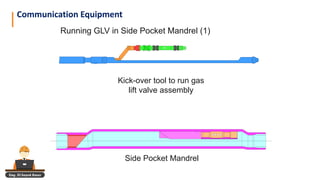

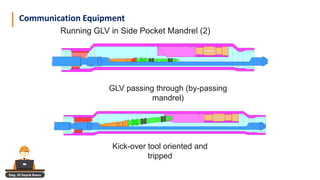

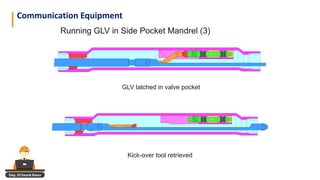

This document discusses side sliding doors and side pocket mandrels. Side sliding doors, also known as sliding sleeves, are used to provide controlled communication between the tubing and casing annulus. They can enable well killing by fluid circulation. Side pocket mandrels are used to install gas lift valves, dummies, or chemicals at intervals along the tubing string. Gas is injected into the tubing/casing annulus and acts on the gas lift valves to lift liquid up the tubing.