1. Gravel pack systems are used to control sand production in weak formations. Gravel is pumped into the annulus around a screen to block fine sand while allowing fluid flow.

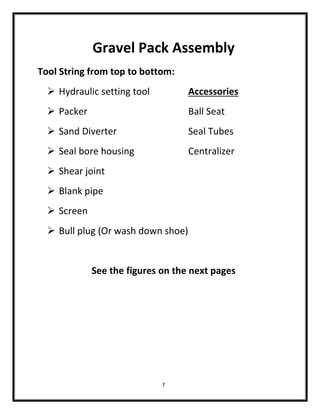

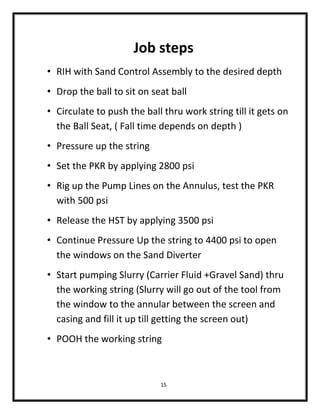

2. The gravel pack assembly includes a packer, screen, blank pipe, centralizer, and bull plug. It is run in hole with the setting tool and packer. Pressure is applied to set the packer and release the setting tool.

3. Gravel slurry is then pumped through the work string, flowing out the window and filling the annulus around the screen. This blocks fine sand while maintaining production.