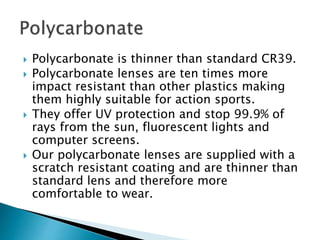

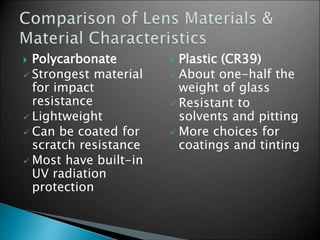

Eye injuries are common in workplaces, with over 2,000 occurring daily and 10-20% resulting in temporary or permanent vision loss. Proper eye protection could prevent around 90% of injuries. There are three ways to prevent eye injuries - assessing hazards, eliminating hazards through measures like machine guarding, and using appropriate eye protection such as laminated, heat-toughened, or chemically-toughened safety lenses made of materials like glass, CR-39 plastic, or impact-resistant polycarbonate.