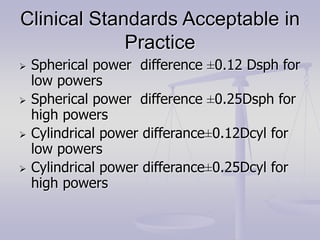

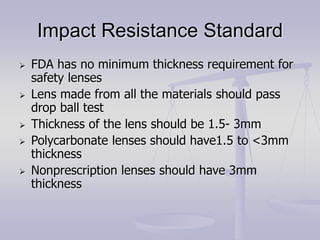

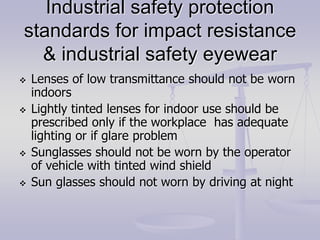

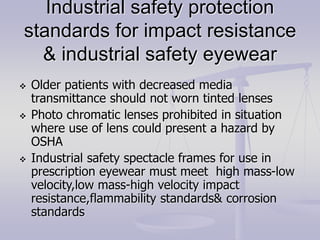

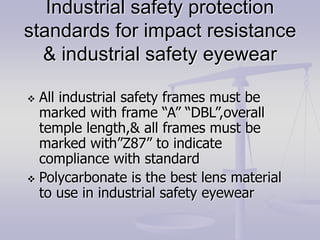

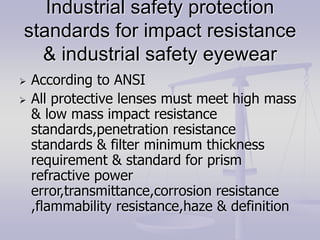

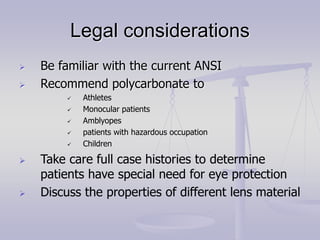

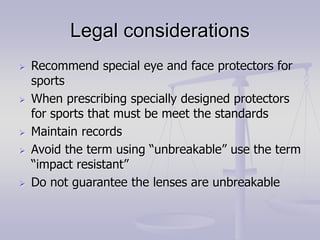

The document discusses standards for ophthalmic lenses and eyewear. It outlines the roles of organizations like ANSI and ISO in establishing voluntary standards to provide quality control and protect public safety. Standards address issues like impact resistance, optical properties, and appropriate lens materials for tasks like industrial safety or sports. Optometrists should be familiar with relevant standards and recommend lenses that meet them to help certain patients like athletes or those with hazardous jobs.