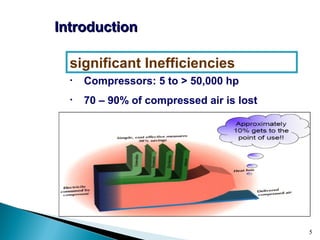

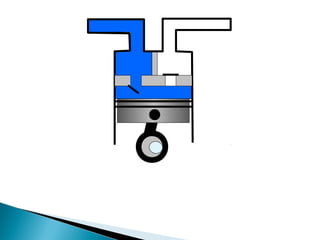

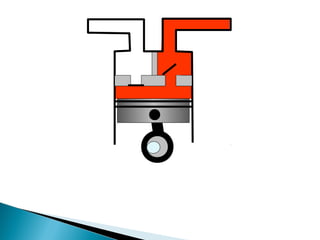

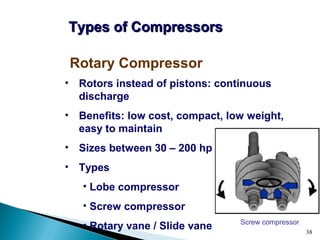

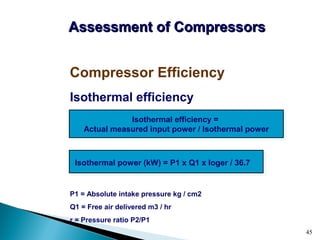

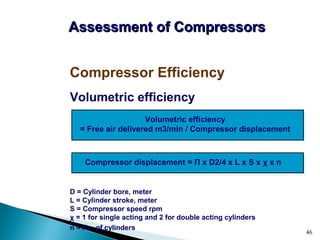

Compressors and compressed air systems were discussed. There are two main types of compressors - positive displacement and dynamic. Positive displacement compressors include reciprocating and rotary types while dynamic compressors include centrifugal and axial types. Proper assessment of compressor capacity and efficiency is important to identify opportunities to improve energy efficiency such as reducing system pressure and minimizing leaks. Maintenance is also key to ensuring optimal performance of compressed air systems.

![48

• Total leakage calculation:

T = on-load time (minutes)

t = off-load time (minutes)

• Well maintained system: less than 10%

leakages

Leak Quantification Method

Assessment of CompressorsAssessment of Compressors

Leakage (%) = [(T x 100) / (T + t)]](https://image.slidesharecdn.com/refrigeration-161219154235/85/Refrigeration-48-320.jpg)