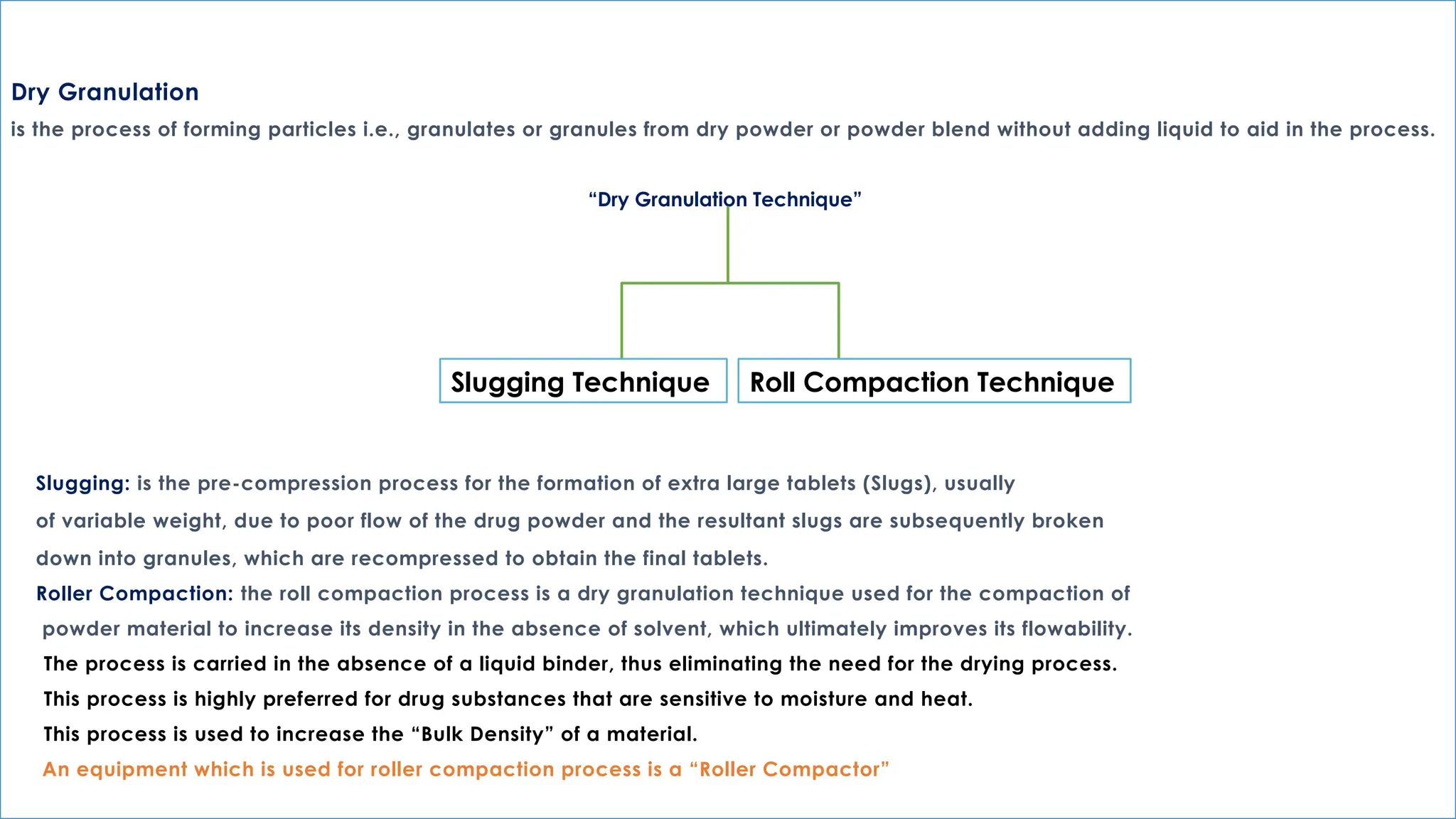

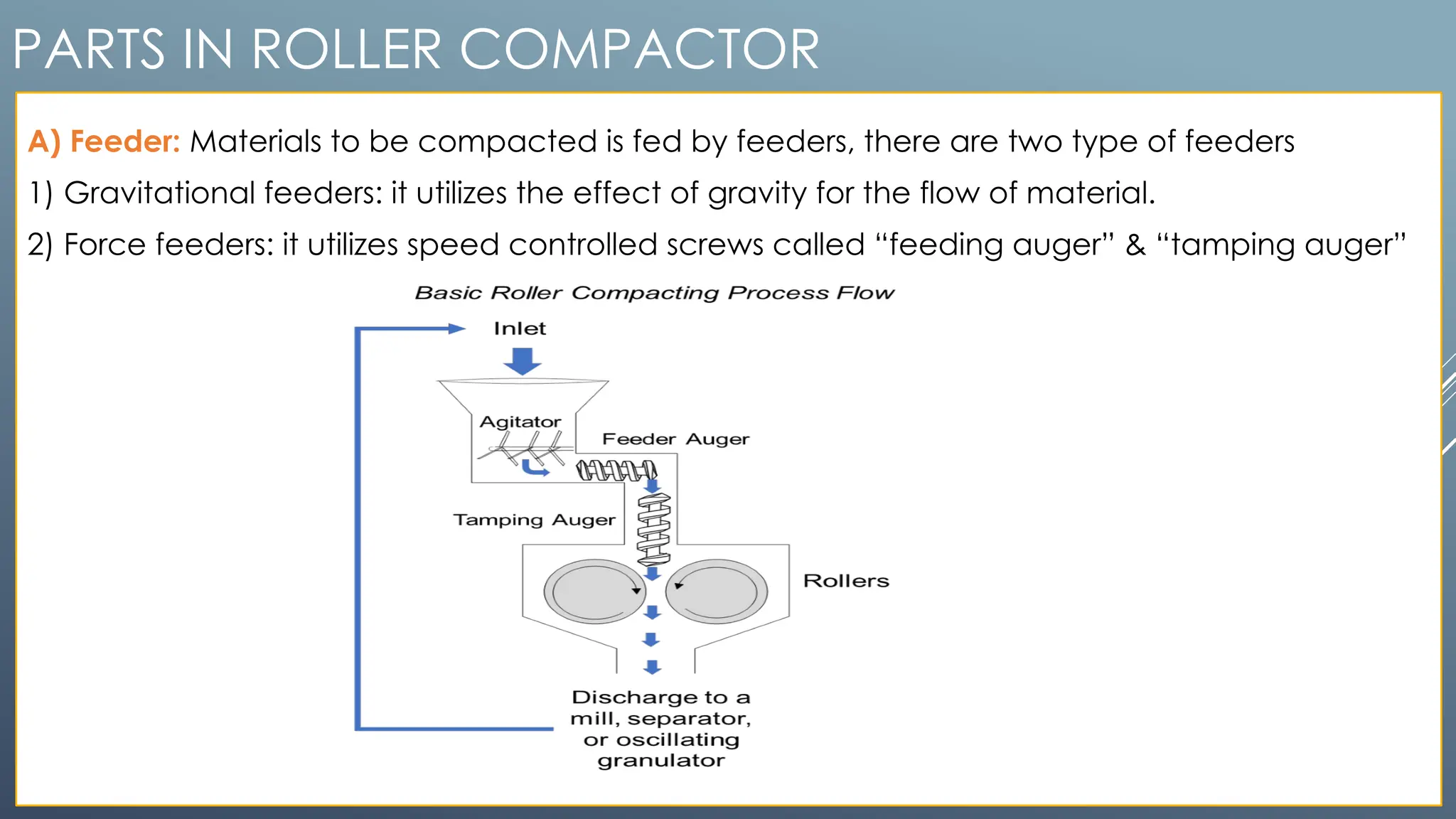

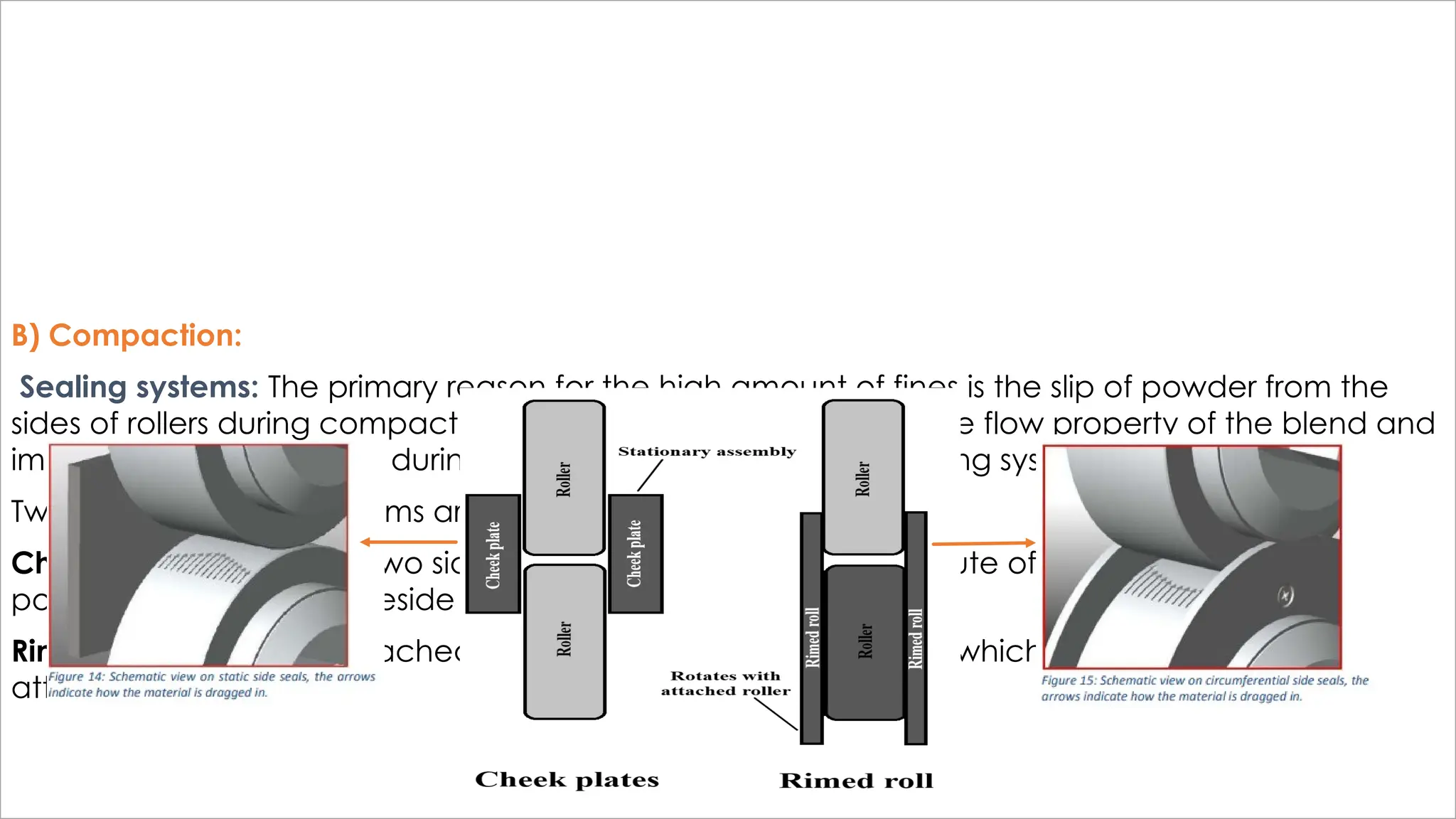

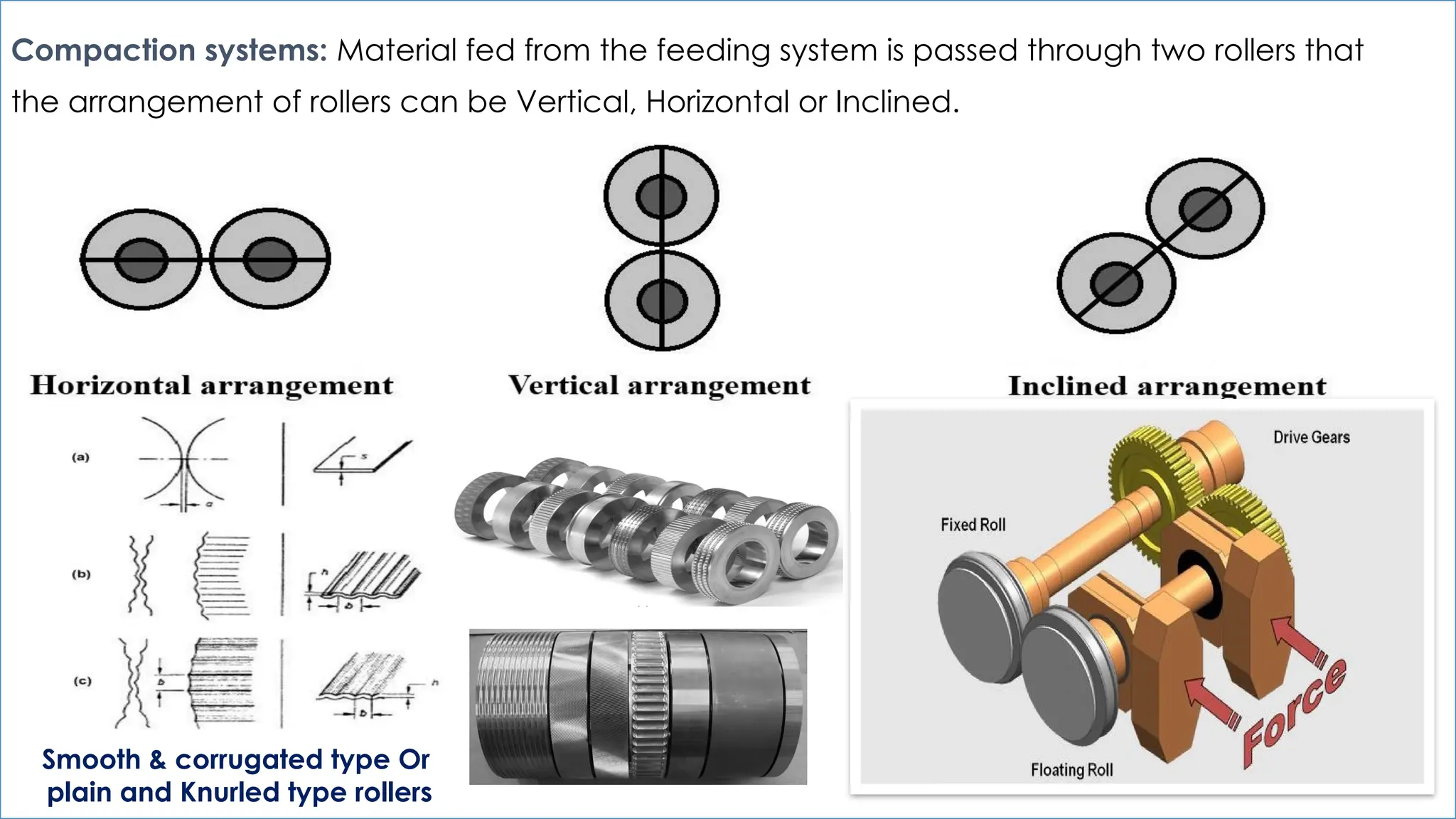

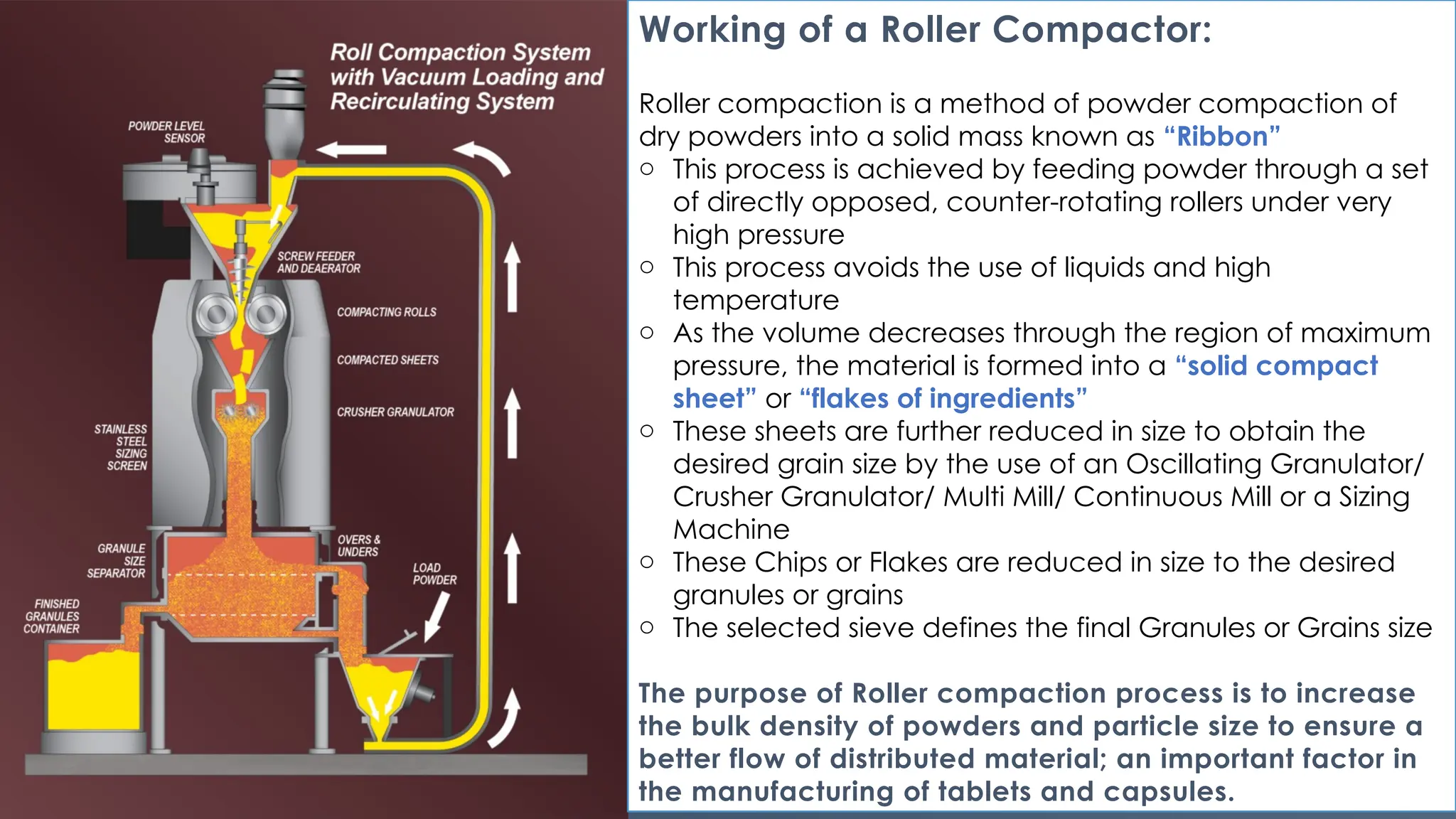

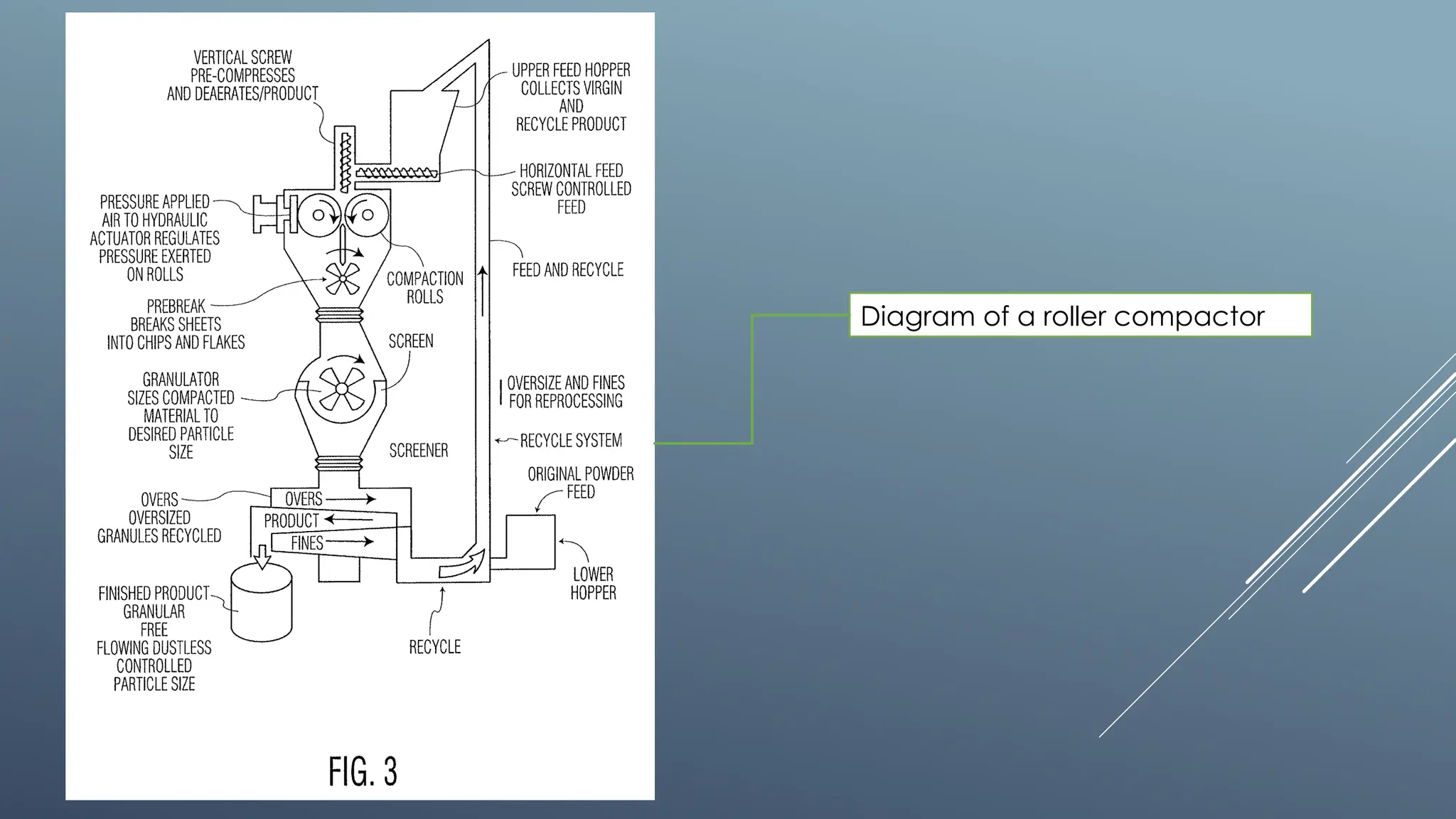

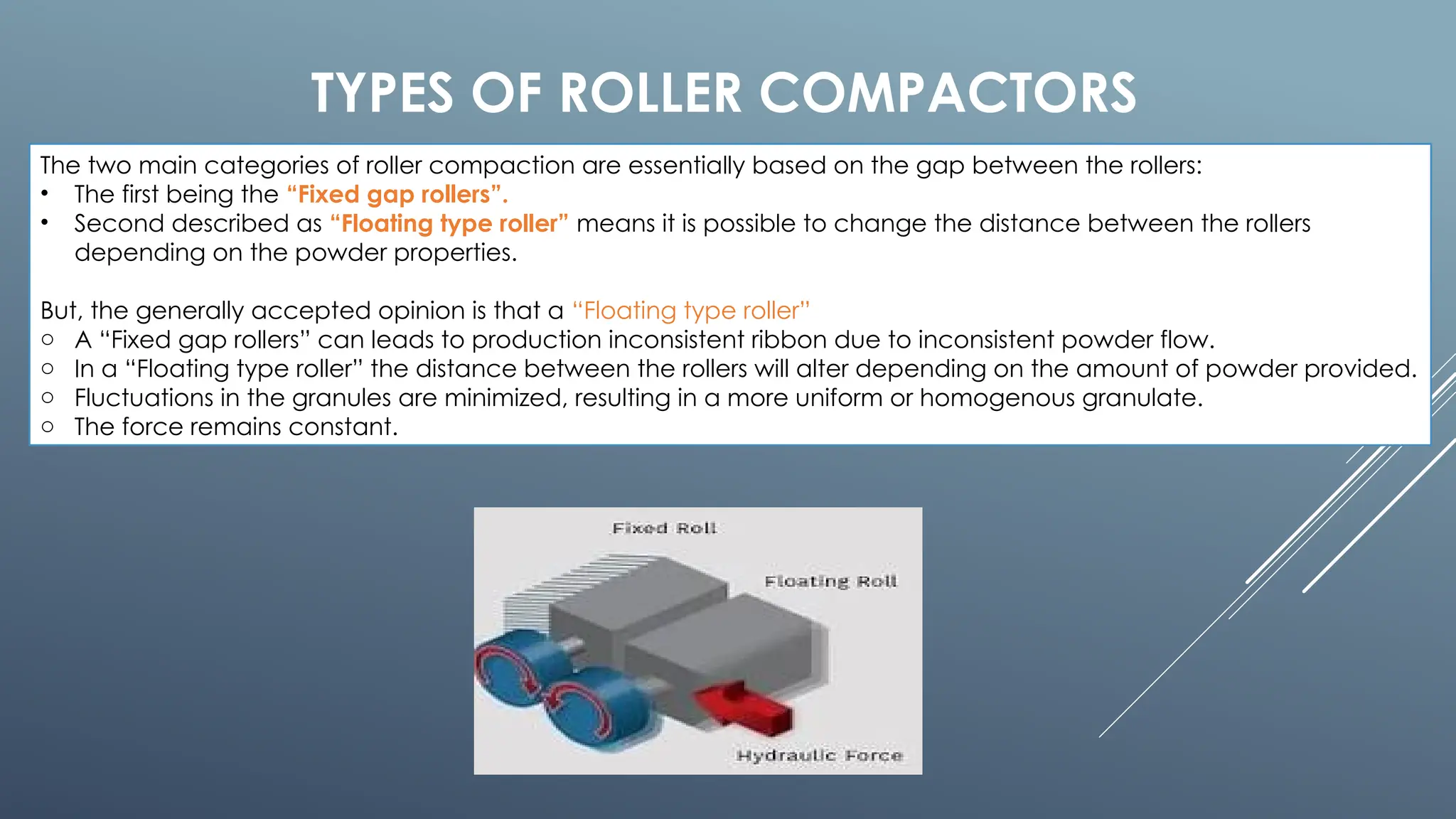

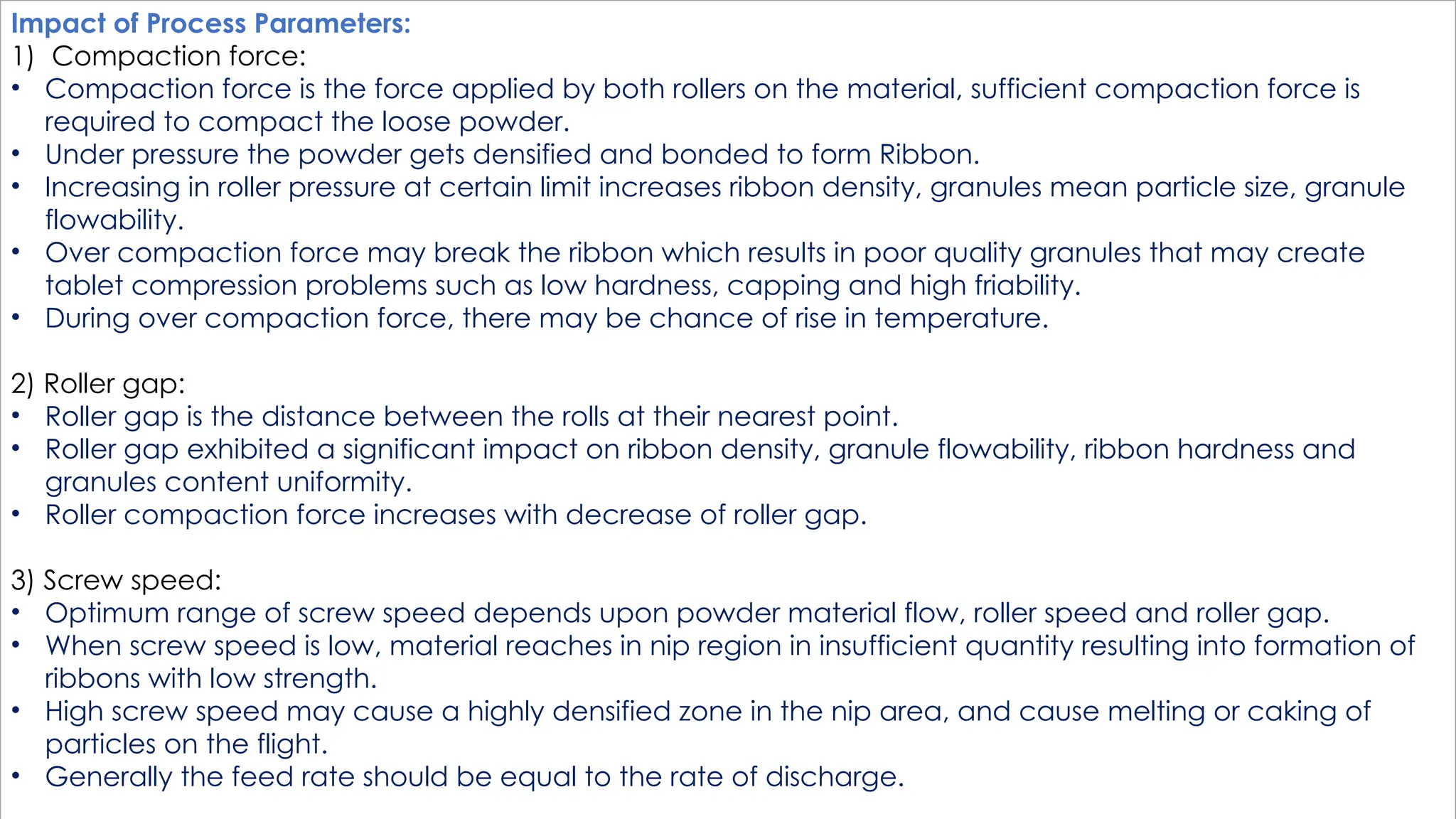

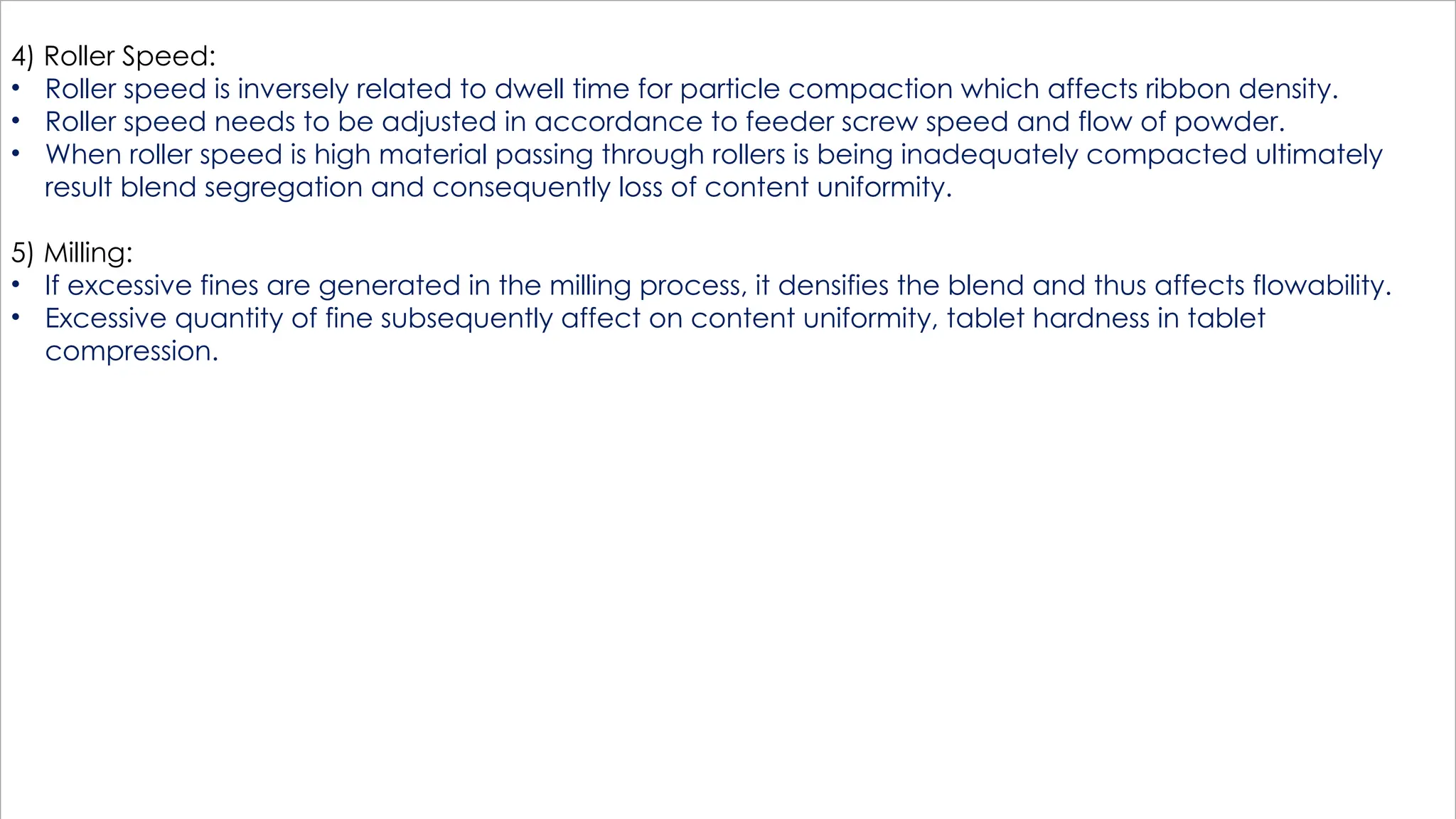

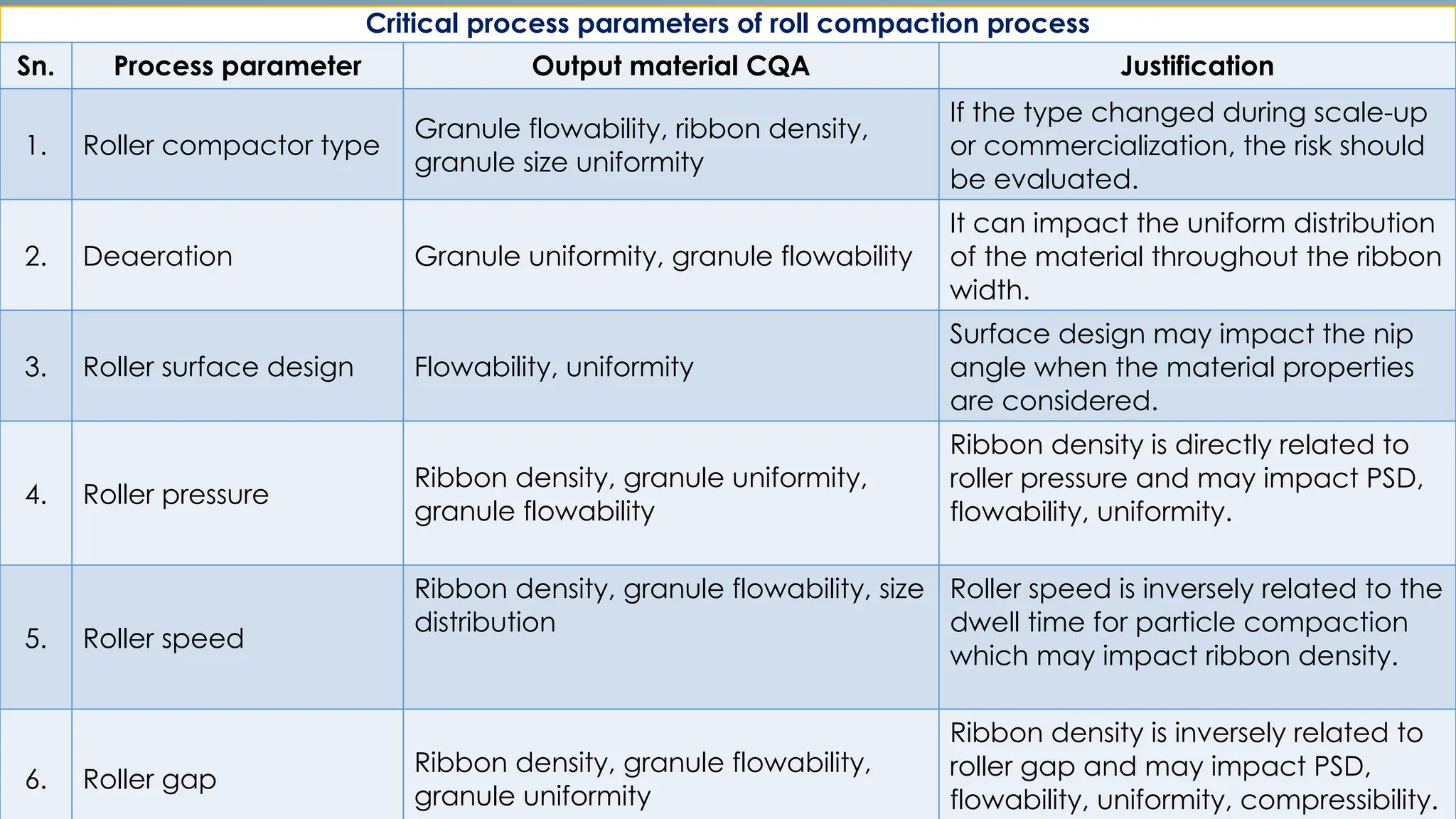

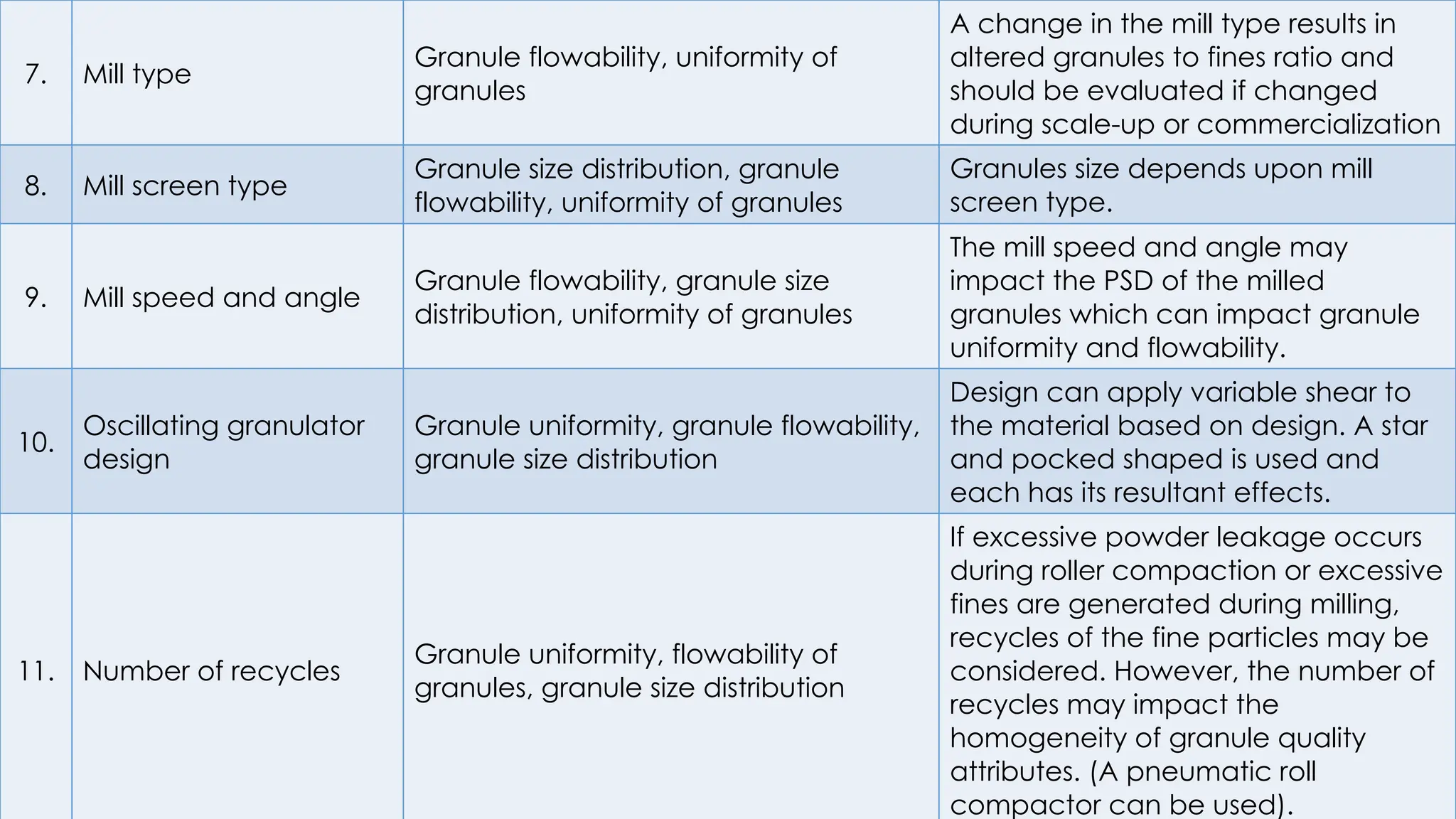

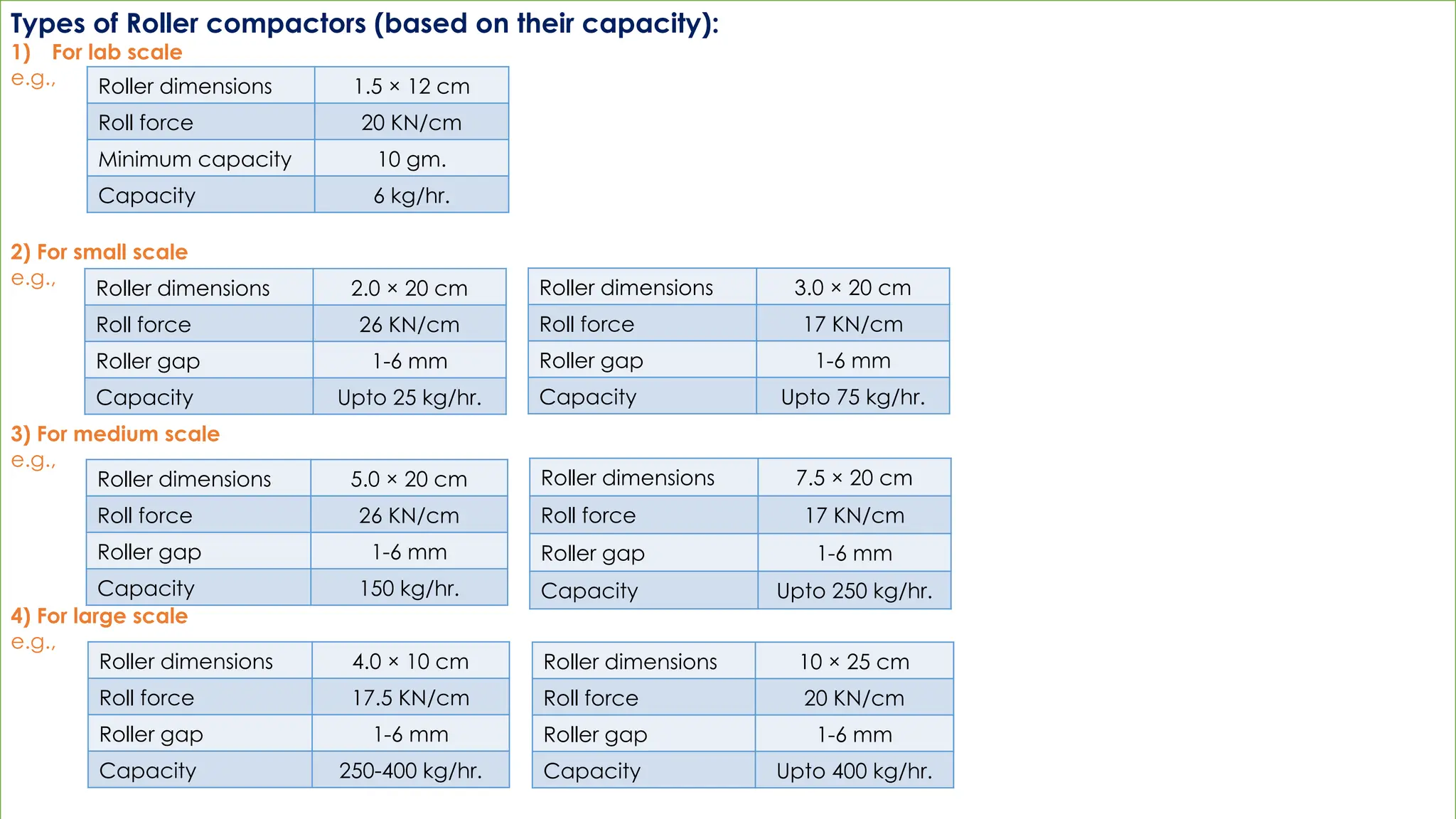

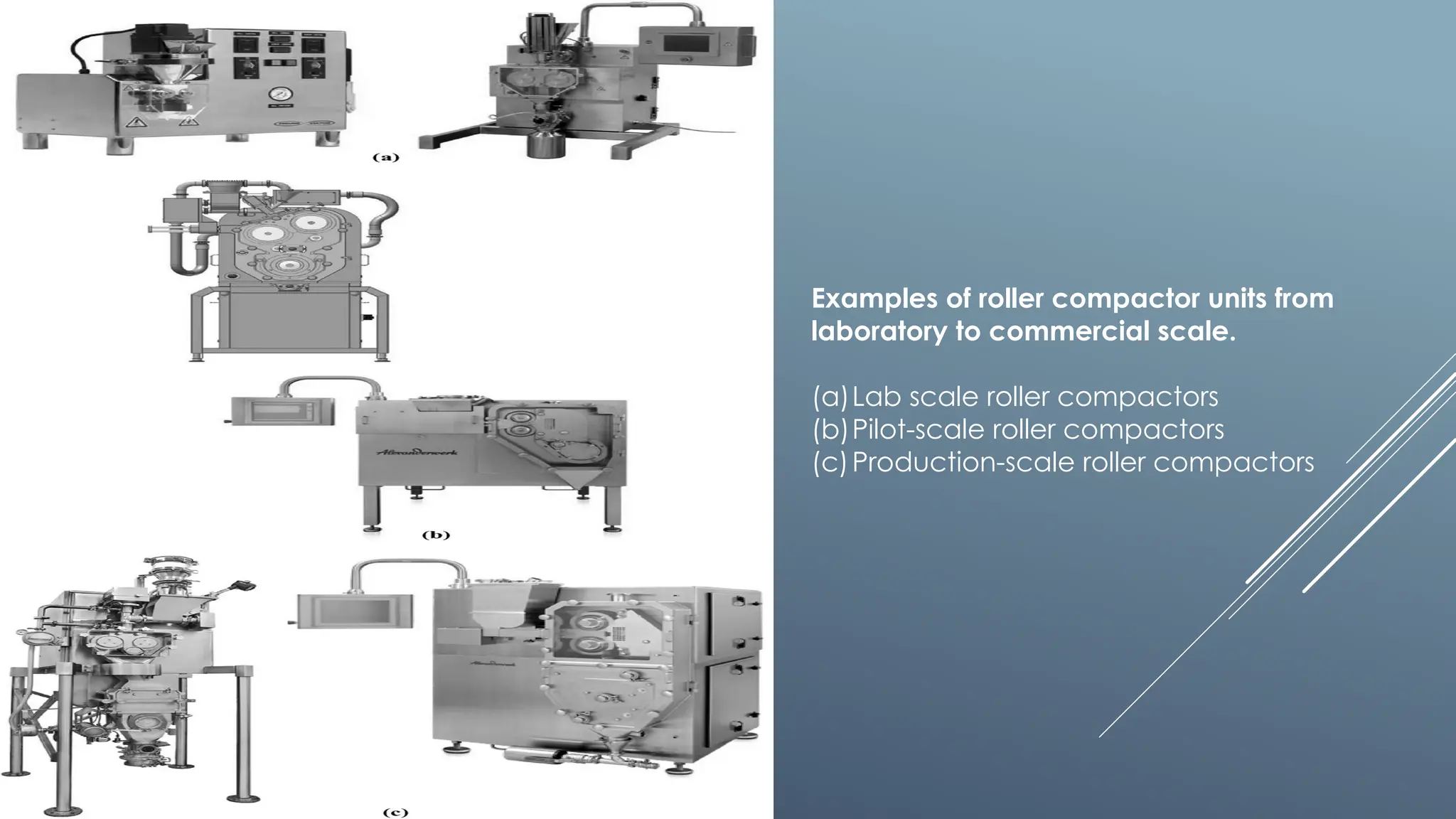

The seminar presented by Jayesh M. Rajput discusses dry granulation techniques, particularly focusing on roller compaction as a method to enhance the density and flowability of powder materials without the use of liquid binders. It details the components of a roller compactor, the compaction process parameters, and their impacts on the quality of granules produced. Optimization of these parameters is crucial for improving efficiency and consistency in tablet and capsule manufacturing.