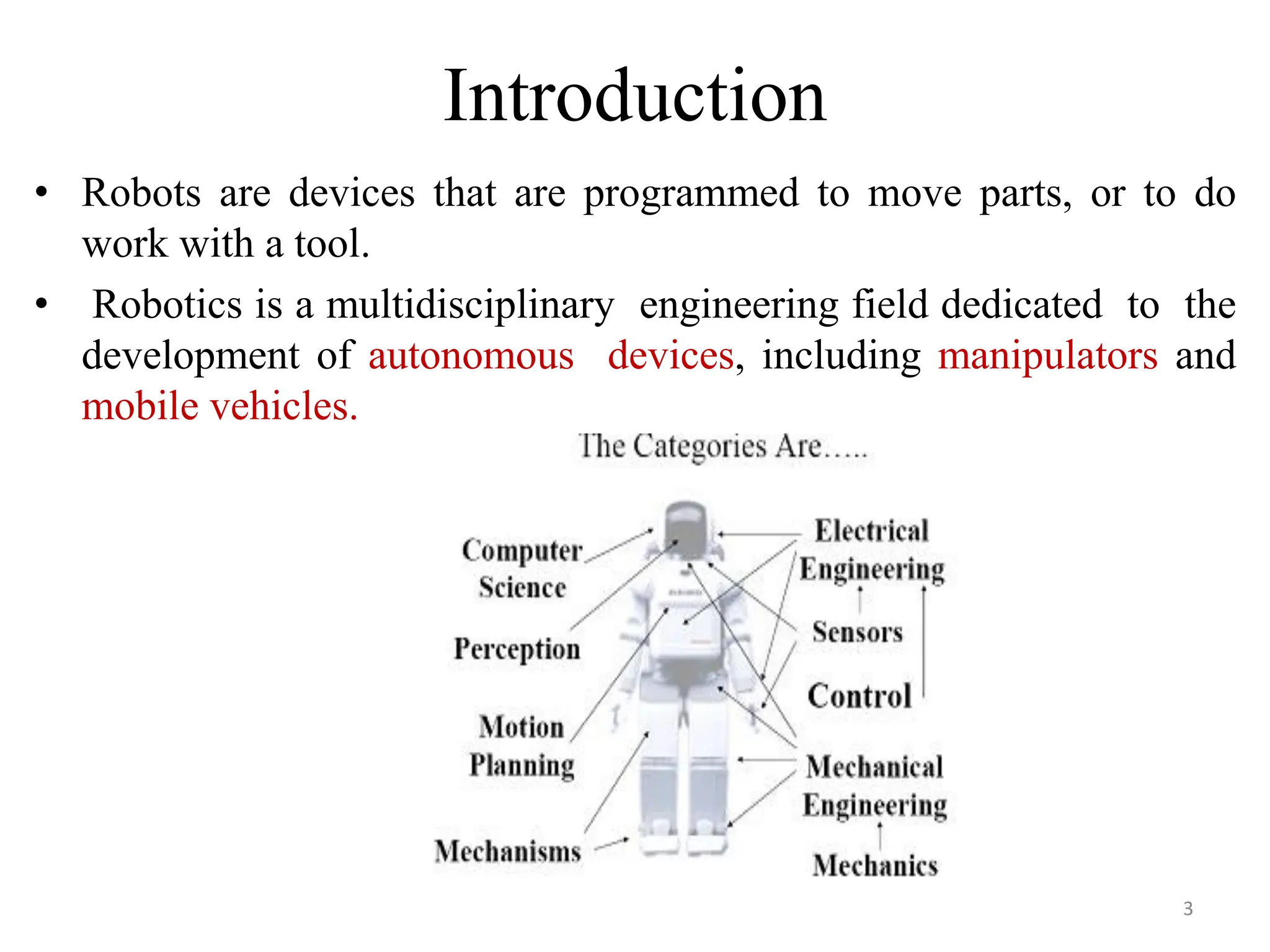

Chapter 5 on industrial robotics covers the basics of robot technology, programming, and applications. It details the anatomy of industrial robots, their various configurations, joint types, and control systems, as well as the roles of end effectors such as grippers and tools. Additionally, it discusses robot programming methods and highlights typical applications in material handling, processing, and assembly.