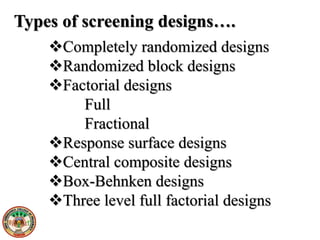

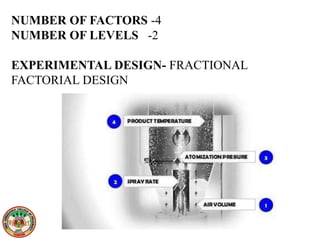

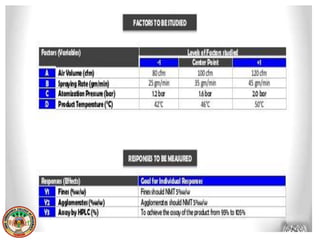

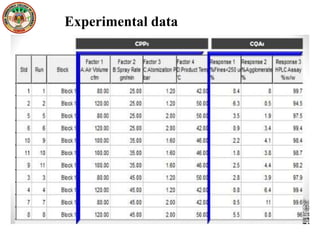

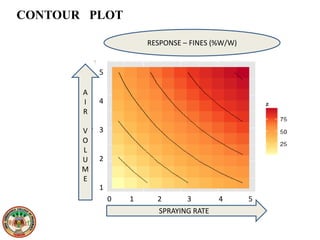

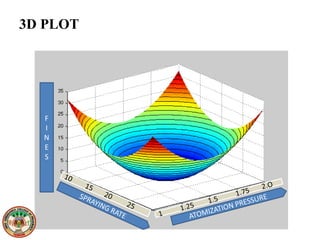

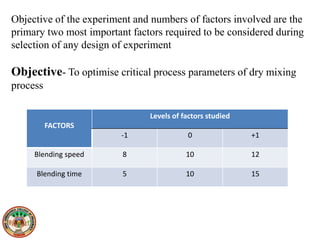

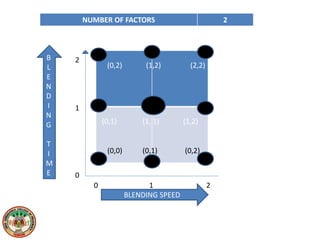

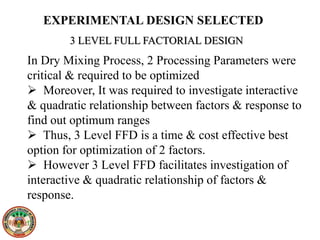

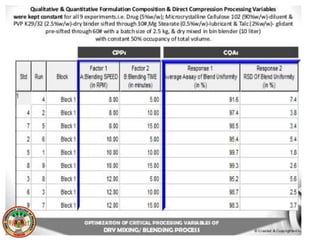

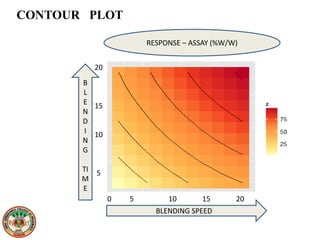

This document discusses various design of experiment methodologies including screening designs and optimization designs. It provides examples of factorial designs, response surface designs like central composite designs and Box-Behnken designs, and three-level full factorial designs. It also gives an example of using a fractional factorial design to screen critical processing parameters in a wet granulation coating process and selecting a three-level full factorial design to optimize two factors, blending speed and time, in a dry mixing process to investigate their interactive and quadratic effects on the response.