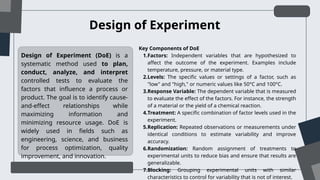

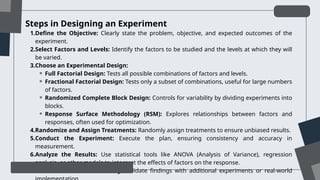

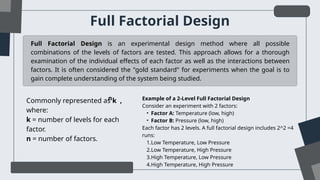

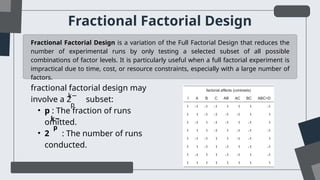

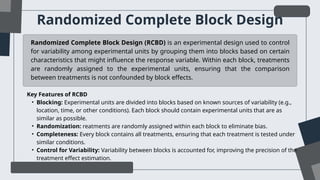

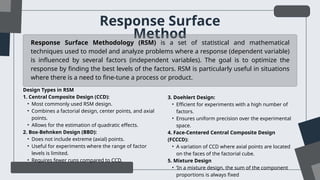

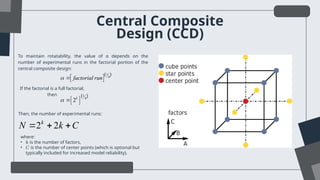

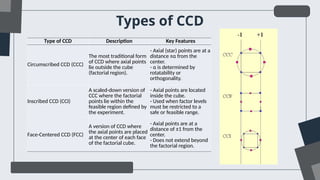

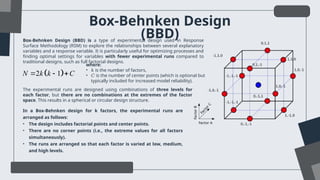

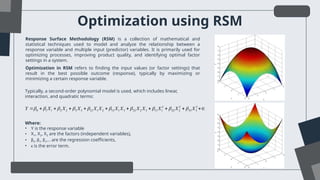

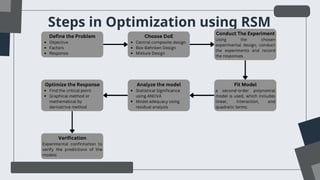

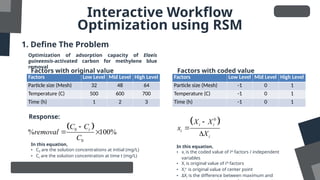

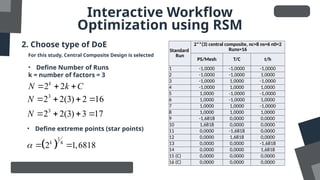

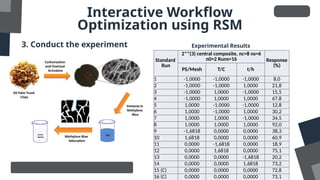

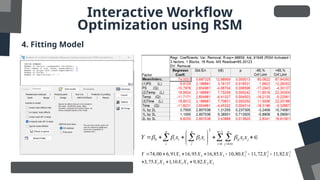

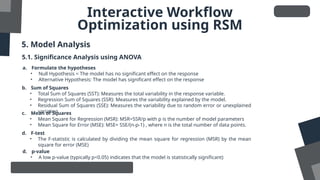

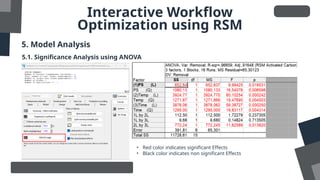

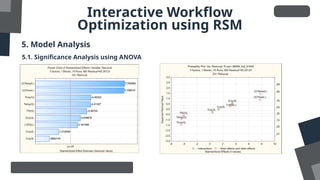

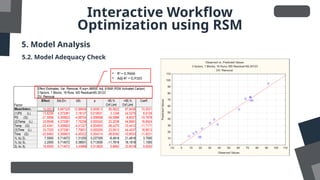

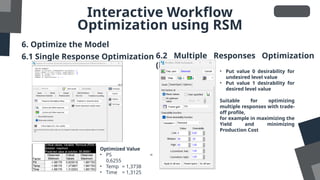

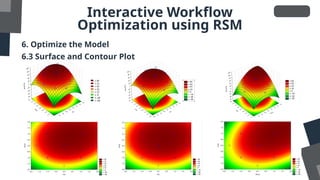

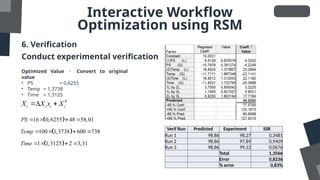

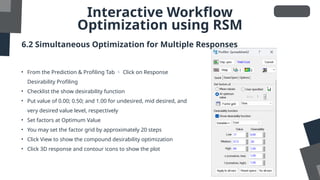

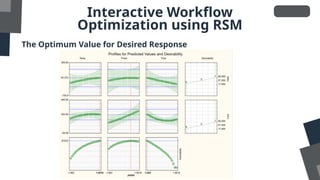

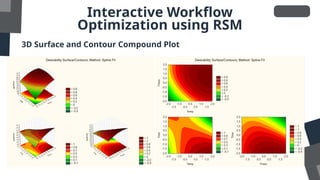

The document discusses the Design of Experiments (DOE) and Response Surface Methodology (RSM) for optimization in various fields such as engineering and science. It outlines the key components of DOE, types of experimental designs, and the steps involved in conducting experiments and analyzing results. Additionally, it demonstrates the application of RSM using TIBCO Statistica, focusing on optimizing the adsorption capacity of activated carbon for methylene blue removal.