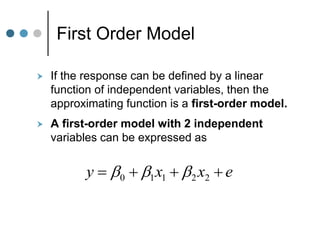

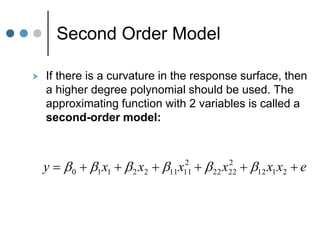

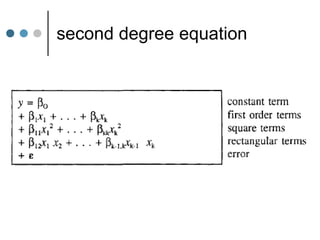

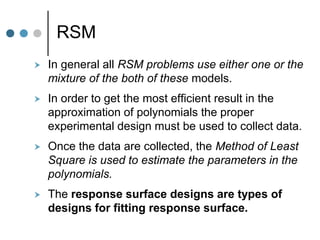

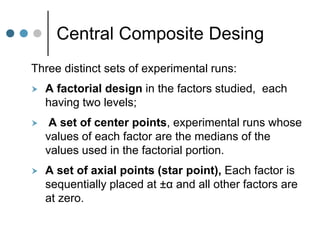

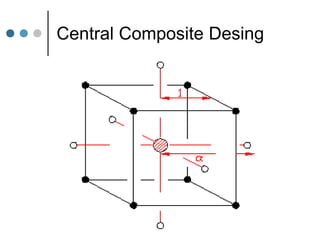

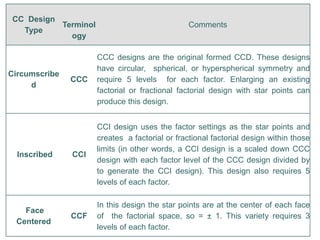

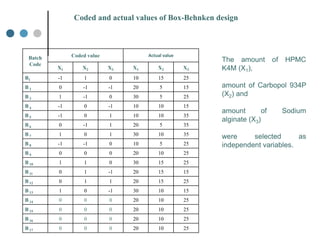

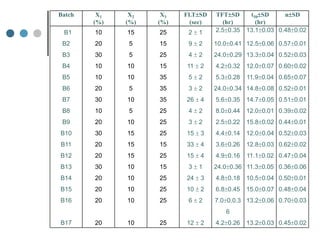

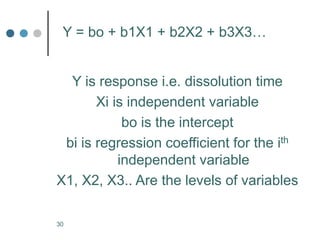

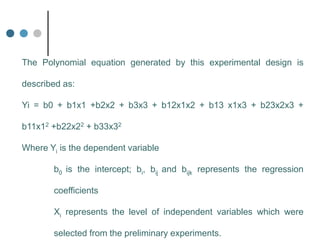

Response Surface Methodology (RSM) uses designed experiments to determine the relationship between several factors and the response. RSM builds a mathematical model to describe this relationship and then uses optimization techniques to find the ideal conditions. Common RSM designs include central composite designs, Box-Behnken designs, and factorial designs. These designs allow modeling of quadratic and interaction effects. The results of RSM experiments are then used to optimize the response through statistical techniques like multiple regression analysis.