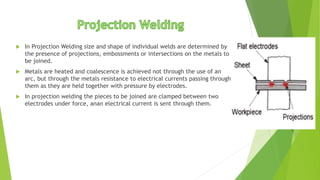

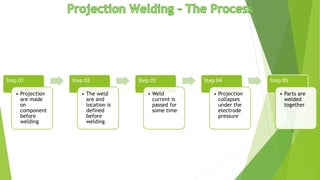

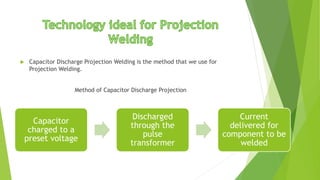

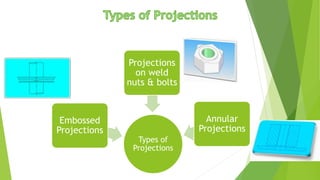

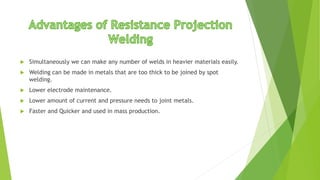

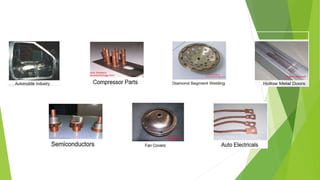

Projection welding is a resistance welding process that joins metal surfaces using heat from electric current, with metal pieces held together under pressure by electrodes. The method involves creating projections on components to be welded, allowing for efficient and simultaneous welding of multiple points, particularly in thicker materials. It is commonly used in applications such as automobile components and sheet metal fabrication due to its speed, lower current requirements, and reduced electrode maintenance.