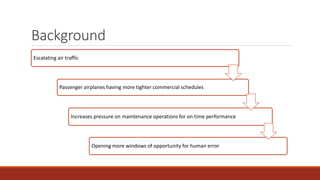

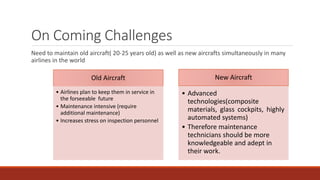

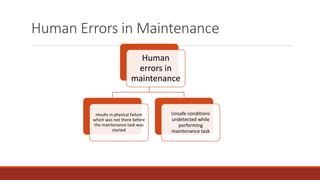

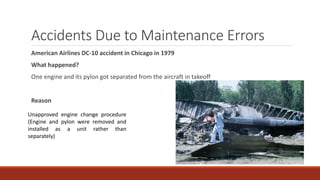

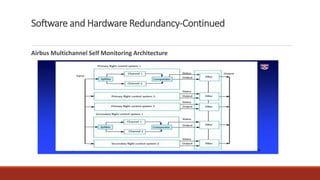

The document discusses the role of human factors in aircraft maintenance and inspection, emphasizing the rising pressure on maintenance operations due to increasing air traffic and aging aircraft. It highlights the risks of human error leading to accidents, the need for clear communication within and among airlines, and the importance of physical demands and adequate working conditions for technicians. Additionally, it covers the necessity for redundancy in flight control systems to reduce pilot workload and enhance safety.