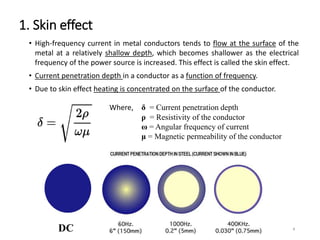

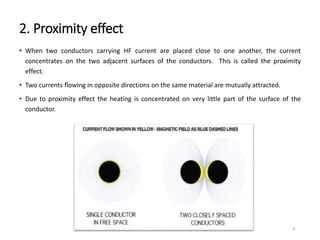

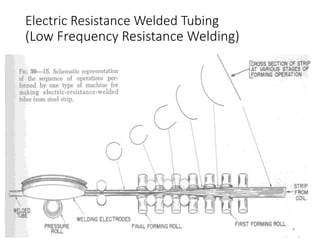

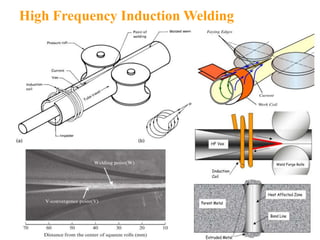

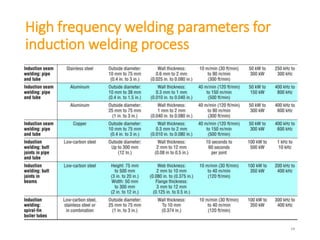

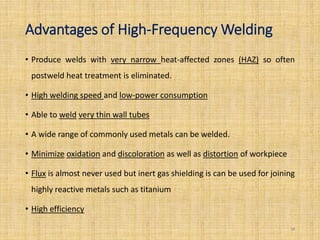

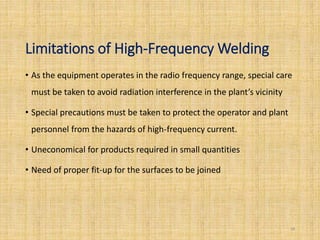

High frequency welding is an automated resistance welding process that utilizes high-frequency currents to generate localized heat for coalescing metals, developed for creating high-integrity joints in pipes and other products. The technique relies on the skin and proximity effects to optimize the welding process, with applications in various metal types and product shapes. Despite its efficiency in welding, it requires careful handling due to radiation concerns and may not be economical for smaller production volumes.

![Some Products of High-Frequency Welding

30[Reference: Welding Handbook, Volume 2, p.665, AWS]](https://image.slidesharecdn.com/highfrequencywelding-190214162759/85/High-frequency-welding-30-320.jpg)