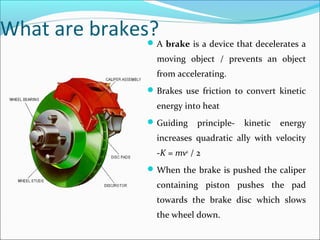

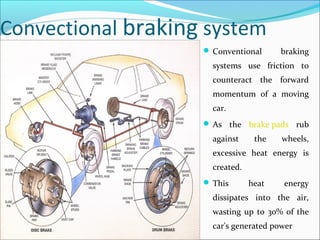

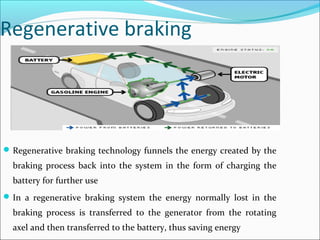

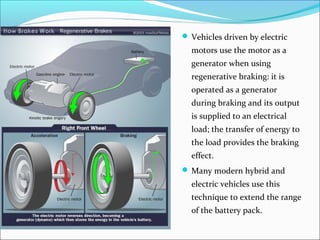

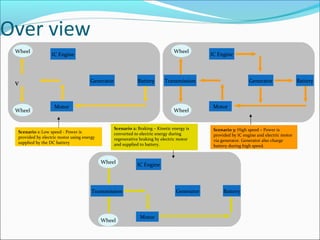

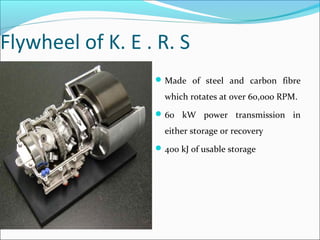

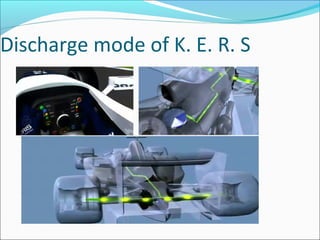

This document discusses regenerative braking systems. It begins with an overview of conventional braking systems and how they waste kinetic energy as heat. It then explains how regenerative braking systems capture this wasted kinetic energy during braking by using the vehicle's electric motor or generator to convert it back into electrical energy for storage in the battery. This recovered energy can then be used to extend the vehicle's driving range. The document covers the key components and working of regenerative braking systems including KERS and their benefits like reduced emissions and increased fuel efficiency. It concludes by noting regenerative braking is not a complete solution on its own due to limitations at low speeds and as a backup in case of failure.