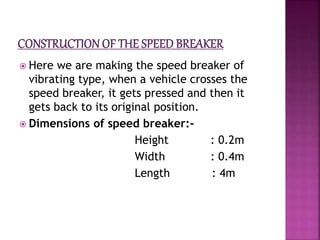

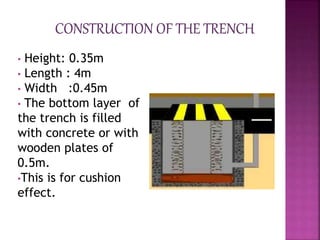

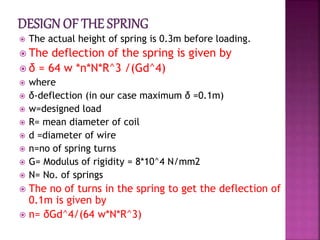

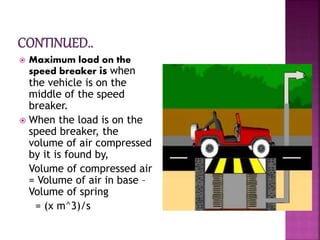

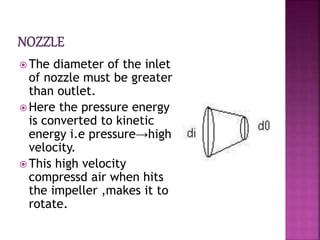

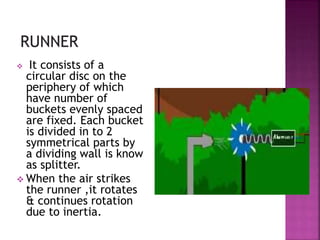

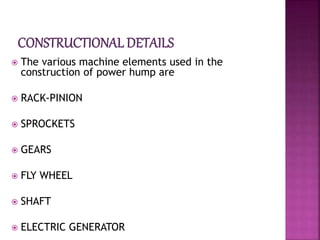

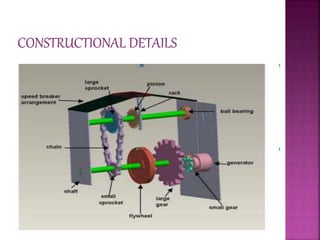

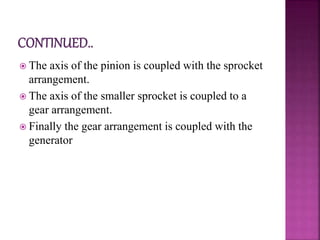

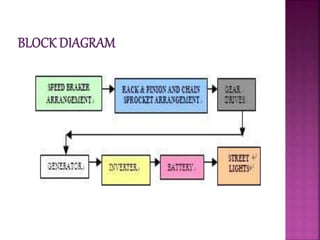

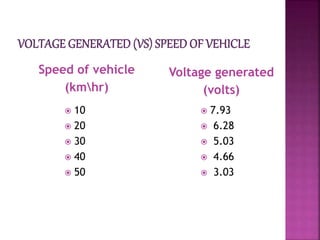

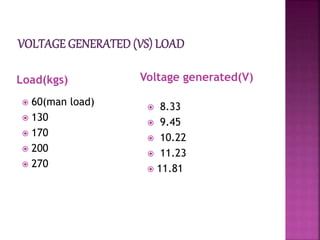

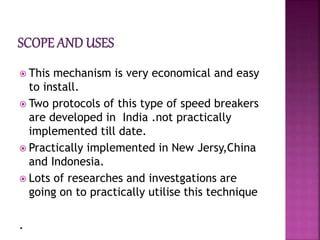

This document describes a design for generating electricity from speed breakers. It includes two mechanisms - a spring coil mechanism and rack pinion mechanism. When a vehicle passes over the speed breaker, the mechanical energy is converted to pneumatic and then electrical energy. The pneumatic energy compresses air that turns an impeller connected to a generator, producing electricity. Design details are provided on the speed breaker dimensions, types of mechanisms considered, energy conversion process, and experimental voltage outputs for different vehicle speeds and loads. The document concludes this technique can help utilize wasted energy at speed breakers.