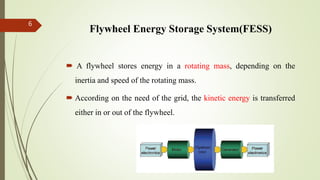

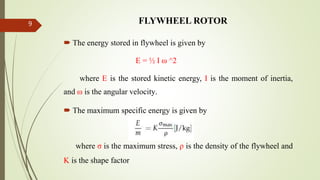

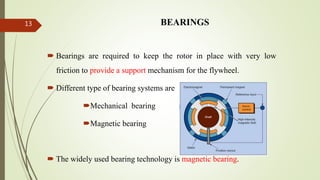

The document discusses flywheel energy storage systems (FESS). It first provides an introduction to energy storage and defines FESS. It then reviews literature on FESS technology and applications. The main components of FESS are described as the flywheel rotor, electric machine, power electronics, bearings and housing. Examples of FESS applications discussed include use in the Porsche 911, transportation, railways, and spacecraft. FESS provide advantages like high power capability and long lifespan but also have limitations such as potential energy losses over time.

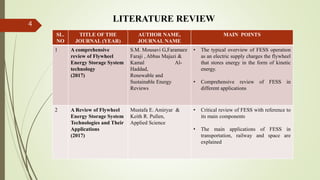

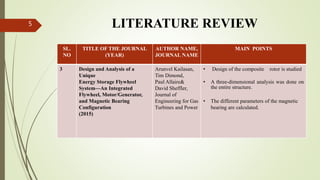

![REFERENCE

Arunvel Kailasan,Tim Dimond,Paul Allaire&Da Sheffler, Design and Analysis

of a Unique Energy Storage Flywheel System—An Integrated Flywheel,

Motor/Generator,and Magnetic BearingConfiguration/Journal of Engineering

for Gas Turbines and Power APRIL 2015, Vol. 137 / 042505

Mustafa E. Amiryar & Keith R. Pullen, A Review of Flywheel Energy Storage

System Technologies and Their Applications/Applied Science Appl. Sci.

2017,Vol.286,7

S.M. Mousavi G et al, Renewable and Sustainable Energy Reviews /Renewable

and Sustainable Energy Reviews 67(2017)477–490

24

[1]

[2]

[3]](https://image.slidesharecdn.com/flywheelenergystoragesystem-171030014901/85/Fly-wheel-energy-storage-system-24-320.jpg)