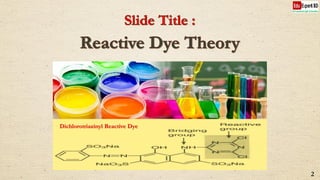

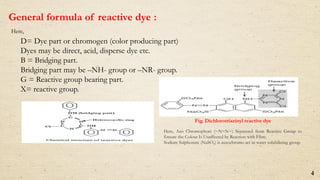

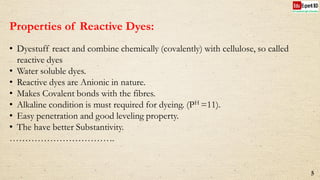

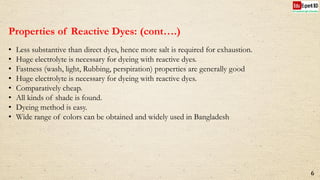

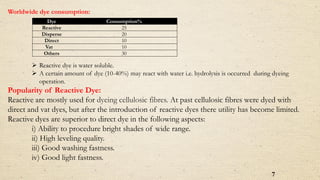

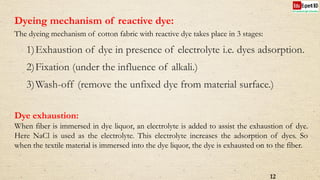

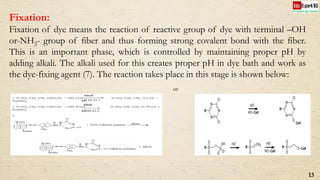

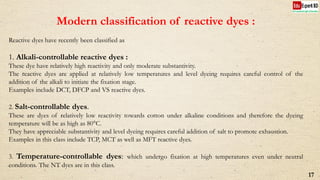

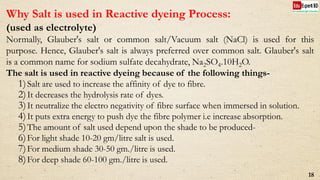

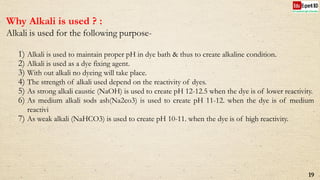

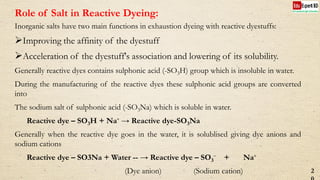

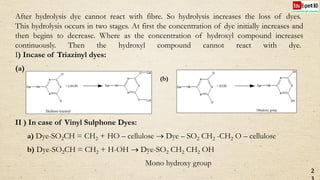

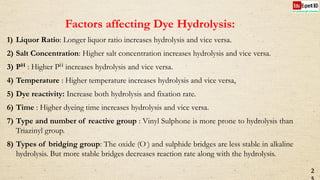

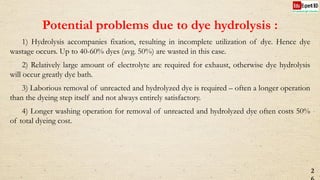

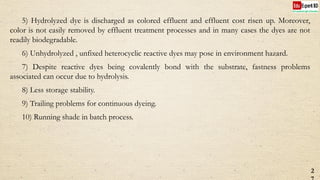

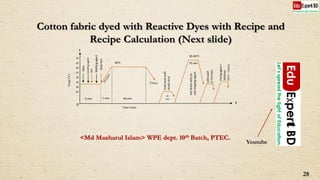

This document provides information about reactive dyes used for dyeing cotton fabrics. It discusses the general structure and properties of reactive dyes, including that they form covalent bonds with fibers. The document also summarizes the dyeing process, which involves dye exhaustion, fixation in an alkaline environment, and washing off unfixed dye. Factors that affect dye hydrolysis are outlined, such as liquor ratio, salt concentration, and temperature. The role of salt and alkali in the dyeing process is also explained.