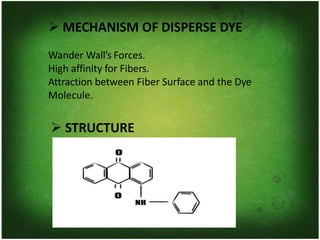

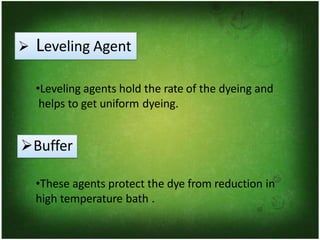

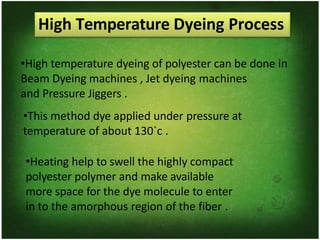

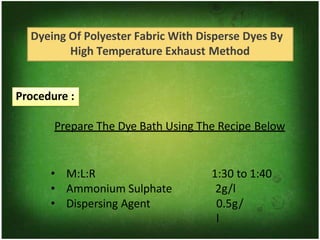

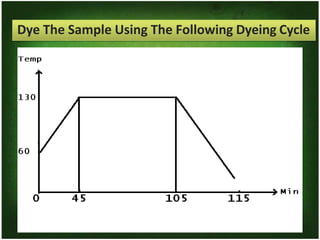

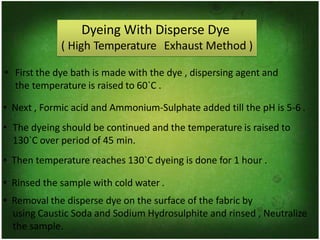

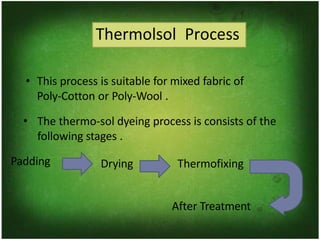

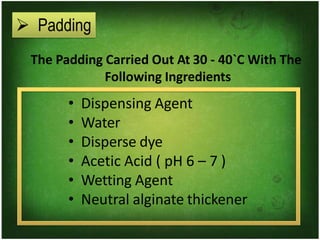

This presentation discusses disperse dyes and their use for dyeing synthetic fibers like polyester and acetate. It provides details on the mechanism of disperse dyeing, including wandle wall forces and fiber affinity. It also outlines the structure, solubility, chargeability and environmental behavior of disperse dyes. Application methods like high temperature dyeing and thermosol processes are summarized, including dye bath recipes and temperature cycles. The presentation concludes with information on dye fastness properties and color ranges for disperse dyes.