Reinforced cement concrete (RCC) is a composite material made of cement concrete reinforced with steel bars. Some key points:

- François Coignet built the first reinforced concrete structure, a four story house in Paris in 1853.

- RCC is used in the construction of columns, beams, footings, slabs, dams, water tanks, tunnels, bridges, walls and towers due to its high strength and durability.

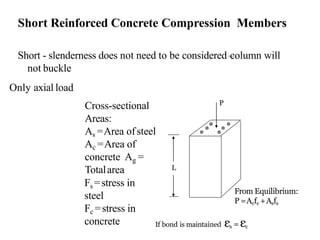

- The steel reinforcement provides tensile strength, while the concrete primarily resists compressive forces and protects the steel from corrosion. Together they form a very strong, stable structural material.