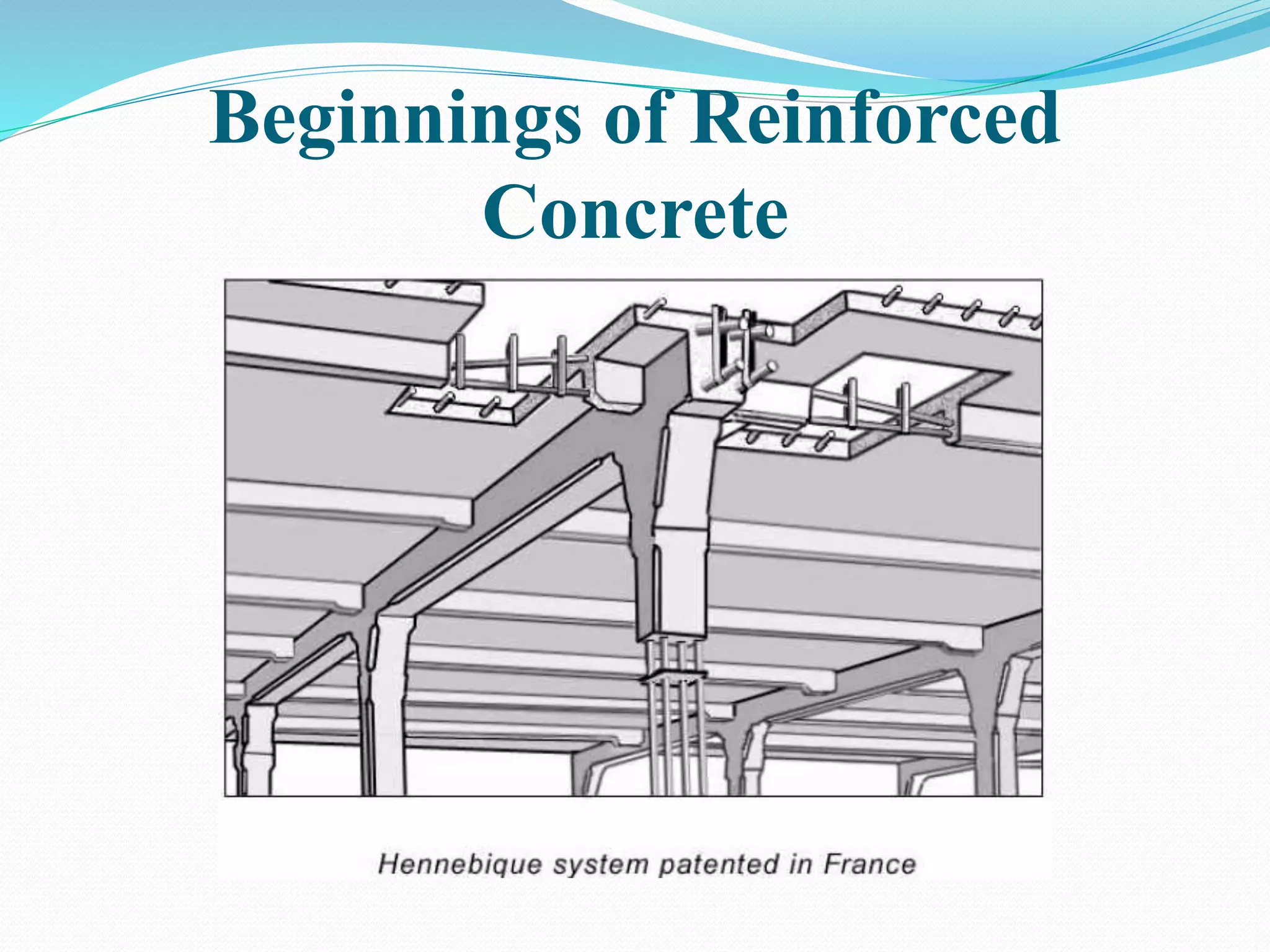

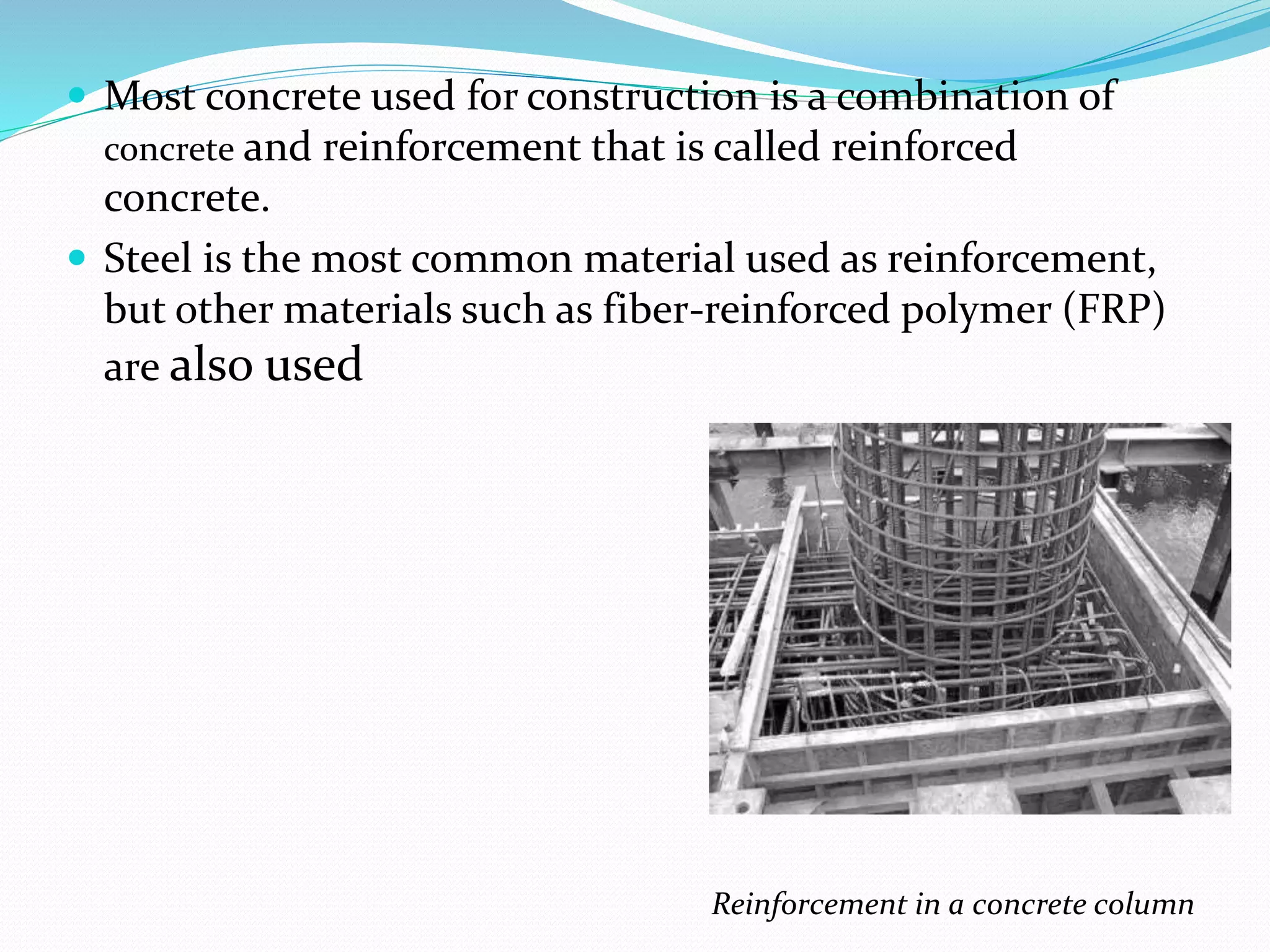

Reinforced concrete is a composite material consisting of concrete and steel reinforcement. François Coignet built the first iron reinforced concrete structure in 1853. Reinforced concrete uses the strengths of both materials - concrete is strong in compression and steel is strong in tension. It is used widely in construction for buildings, bridges, tunnels and other structures due to its high strength and durability.