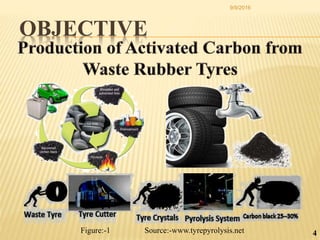

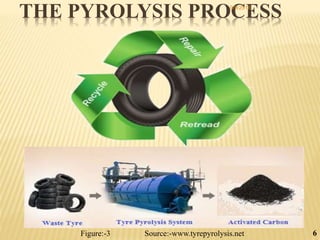

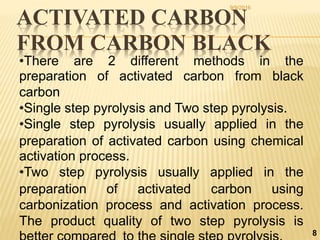

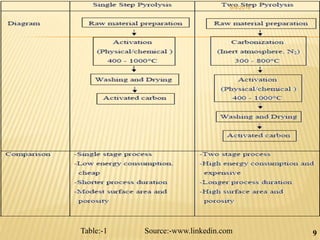

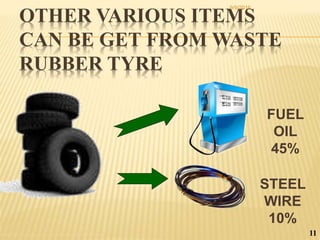

The document discusses recycling waste tires to produce activated carbon. It begins with an introduction to tires and activated carbon. The objective is to describe the recycling process and how it is used to produce activated carbon from carbon black. The recycling process involves collection, sorting, shredding, steel removal, grinding, and distribution. The pyrolysis process breaks down the tires into carbon black, oil, steel, and fuel. There are single-step and two-step methods for producing activated carbon from the carbon black. Activated carbon has various applications in food/beverages, oil refining, water treatment, and other industries. The conclusion is that activated carbon production from waste tires is an effective use of this harmful waste and creates a useful