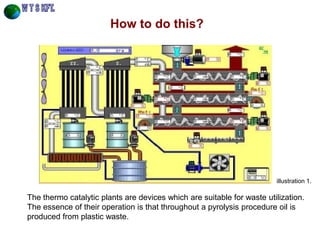

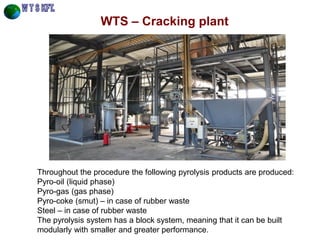

The document discusses fuel extraction from plastic waste through a process called pyrolysis. Pyrolysis involves heating plastic waste in an oxygen-free environment to produce pyro-oil, pyro-gas, and pyro-coke. While pyrolysis can utilize plastic waste, it has disadvantages like the produced outputs having high chlorine, sulfur, and hydrocarbon content which require further processing. Due to these serious disadvantages, the authors decided to rebuild the system to use catalytic cracking instead for plastic waste processing.