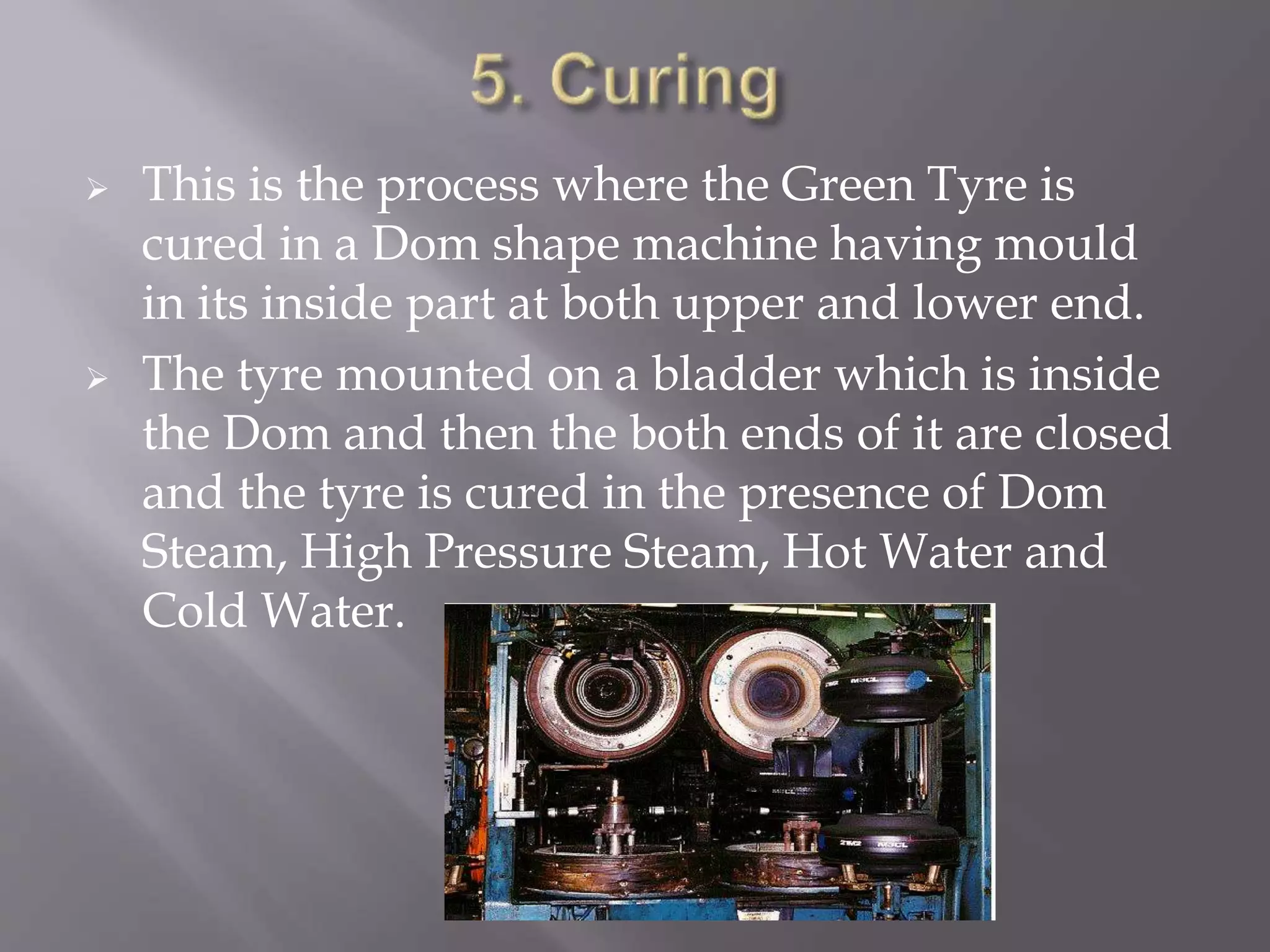

The document outlines the manufacturing process of radial tyres by the first Indian company to do so, highlighting their market share and partnerships with major automotive manufacturers. It details the various steps involved in tyre production, including blending, extruding, calendering, curing, and inspection, emphasizing the need for skilled labor and adherence to specific rules for effective production. The document also notes the importance of quality checks through manual and automated inspections.