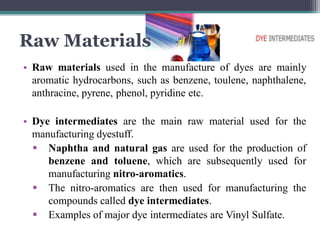

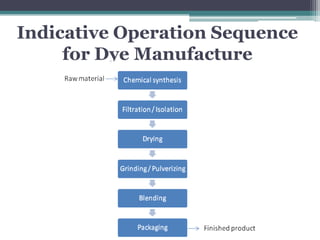

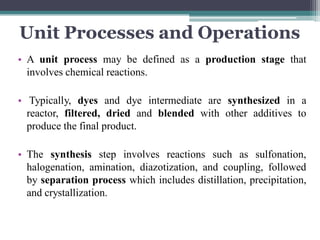

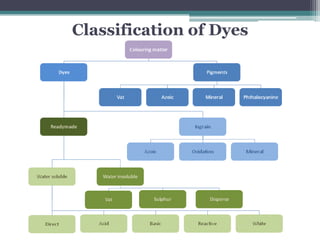

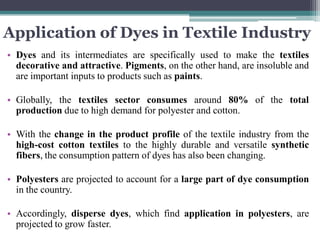

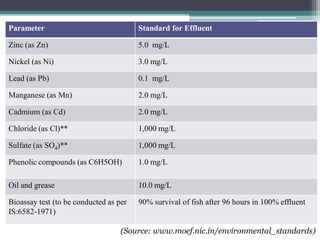

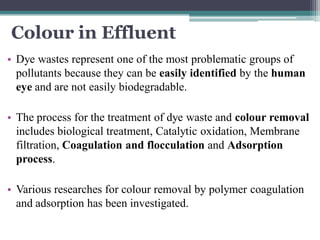

The document details the dye and dye intermediate industries in India, outlining their production processes, classification, environmental impacts, and wastewater treatment challenges. It emphasizes the high pollution levels associated with dye manufacturing, including hazardous waste generation and strict effluent discharge standards. Various treatment methods and technologies for managing dye wastewater are discussed to mitigate environmental impact.