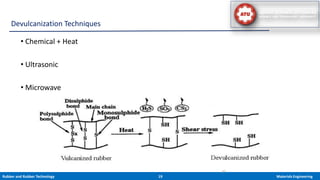

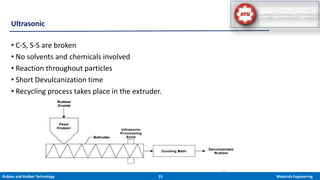

The document discusses the environmental impacts of rubber manufacturing and the importance of recycling rubber to mitigate pollution and waste. It outlines various types of rubber waste, production processes, and recycling methods, including grinding and devulcanization techniques. Additionally, the document highlights the benefits of rubber recycling in terms of energy savings and resource recovery.