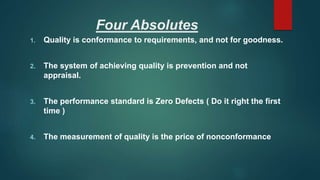

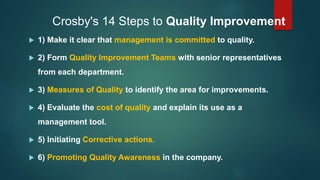

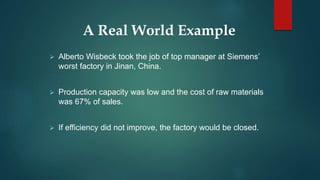

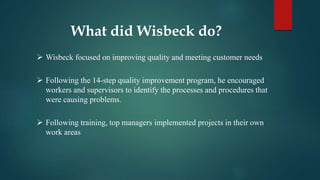

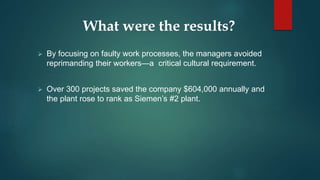

Philip B. Crosby was an American quality management expert known for developing the concepts of "quality is free" and "zero defects". His 14 steps for quality improvement process focused on prevention over inspection and getting quality right the first time. An example described how a factory manager in China successfully turned around a struggling factory by following Crosby's approach of engaging workers to identify and fix faulty processes, implementing training programs, and focusing on customer needs over blame. This led to over $600,000 in annual savings and improved the factory's performance.