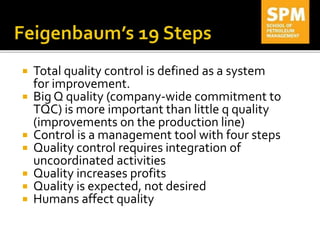

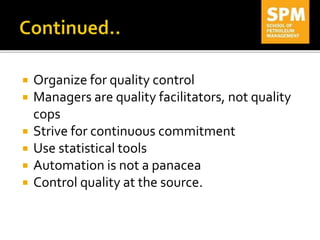

Armand Feigenbaum was an American engineer and quality control expert born in 1922. He is considered the founder of total quality management (TQM). Feigenbaum developed the concept of total quality control, which focused on integrating quality development, maintenance, and improvement efforts across all groups in an organization. He argued that quality should be managed from design to customer satisfaction and viewed as the responsibility of entire companies rather than just production staff. Feigenbaum's work established quality as a management philosophy and key driver of business success.