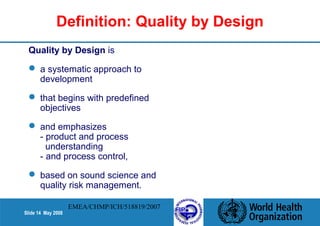

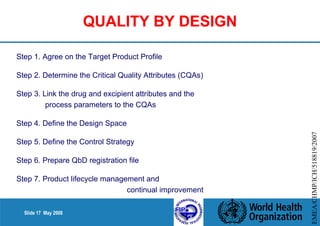

This document summarizes the steps in a Quality by Design (QbD) approach for pharmaceutical development:

1. Define the Target Product Profile to outline the desired quality characteristics.

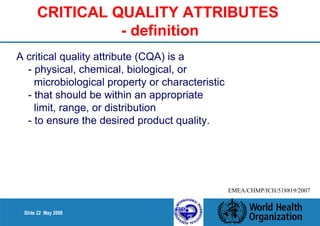

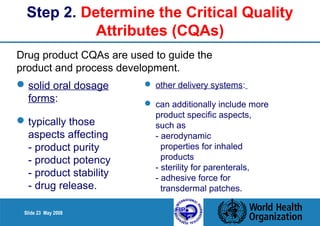

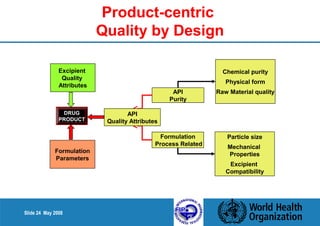

2. Determine the Critical Quality Attributes that ensure the product's safety, efficacy and quality.

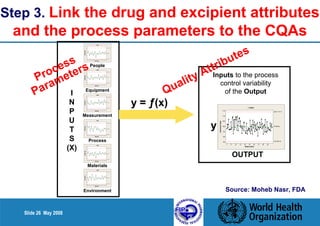

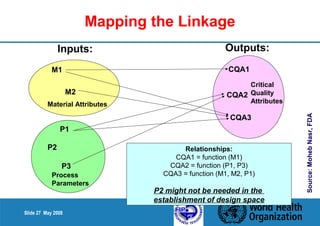

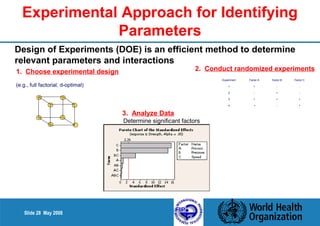

3. Link the material attributes, process parameters and Critical Quality Attributes through experimental studies and risk assessment.

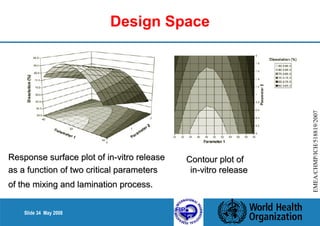

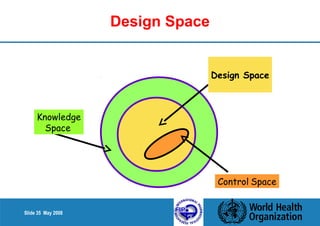

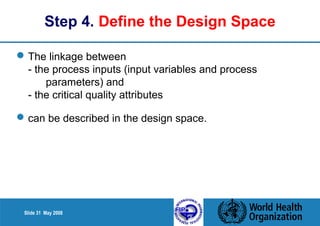

4. Define the Design Space as the multidimensional combination of input variables and process parameters that provide quality assurance.

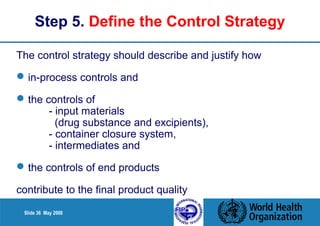

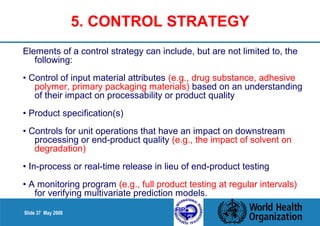

5. Establish a control strategy for inputs, processes and outputs to maintain final product quality within the design space.

![Slide 32 May 2008

Definition of Design Space

The material attributes and process parameters that

assure quality.

The multidimensional combination

and interaction of input variables

(e.g. material attributes) and

process parameters that have been

demonstrated to provide assurance

of quality.

Roll pressure

Gap width

Screen Size

300

200

100

0

-100

Dataset - Run1-10a.M3

Observed vs. Predicted $Time [Last comp.] (Aligned)

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260

$Time (normalized)

SIMCA-P+ 11.5 - 05/02/2007 23:17:07](https://image.slidesharecdn.com/qualitydesign-140920223401-phpapp01/85/Quality-design-32-320.jpg)