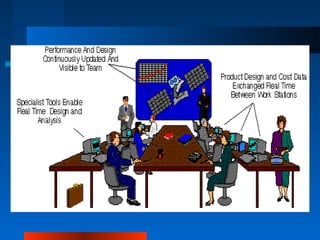

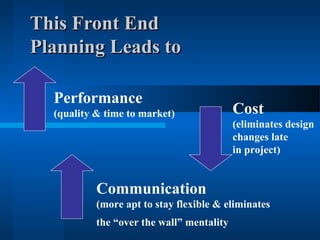

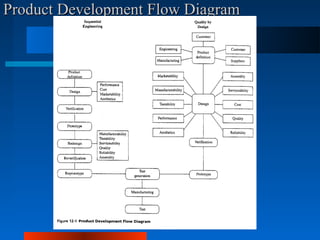

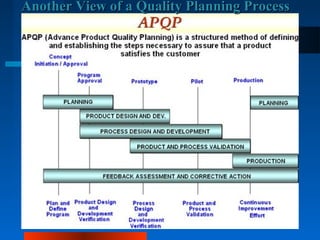

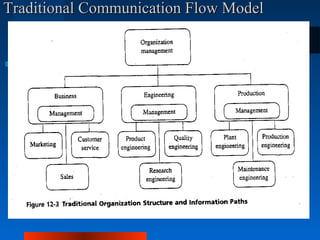

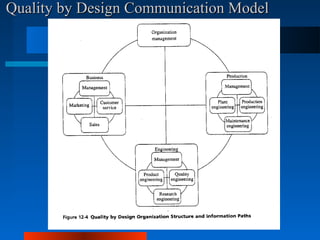

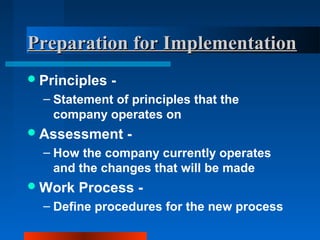

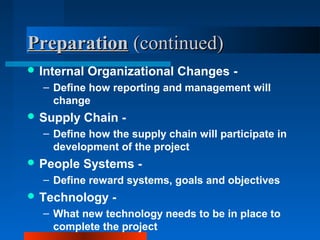

Quality by Design is a practice that uses a multidisciplinary team to simultaneously design products and plan production processes. This concurrent engineering approach aims to develop products that satisfy customer expectations through cooperation and communication across different teams. Implementing Quality by Design requires organizational changes, cross-functional teams, and new communication practices to reduce costs and development time while improving quality, productivity and profits. It utilizes various tools from organizational methods to statistical analysis to support integrated product development.