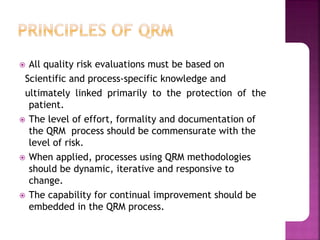

Risk management is a central part of any organization's strategic management. It helps understand potential upside and downside factors that can affect the organization. The key aspects of risk management include risk identification, analysis, evaluation, and assessment to understand probability of success, failure, and uncertainty. It then focuses on risk reduction, control, and acceptance. The overall goal is to increase probability of success while reducing probability of failure and uncertainty of achieving objectives.

![Level Patient Effect Process Effect

10

[Certainty] Availability of

prior

Knowledge/Information/Refe

rence [KIR] that the

phenomenon shall occur

Irreparable damage to

batch/product

Product Quality Attributes

are affected. Possible

regulatory deficiency /

customer query

7

[Uncertain] No KIR available

with possibility of

surprise/stray results.[risk]

Fairly certain of the chances.

4

[Uncertain] No KIR available,

but needs to studied .

Remote possibility of Chance

1

Availability of prior [KIR]

that the phenomenon shall

NOT occur

Almost uncertain no

probability to happen

Risk Management 26](https://image.slidesharecdn.com/qrmpresentation-140701002146-phpapp01/85/Qrm-presentation-26-320.jpg)