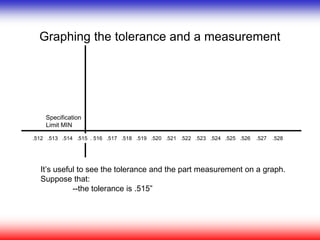

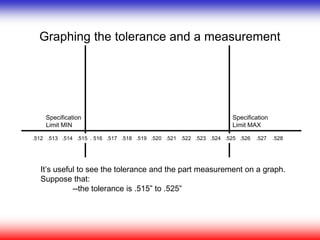

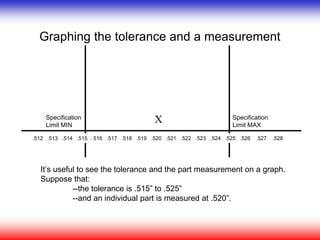

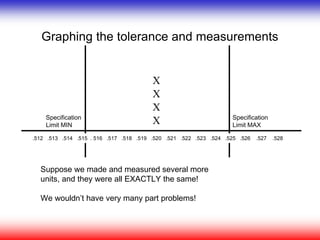

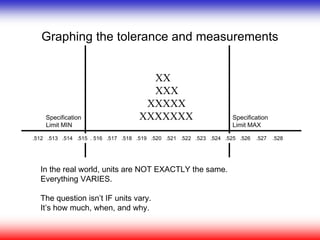

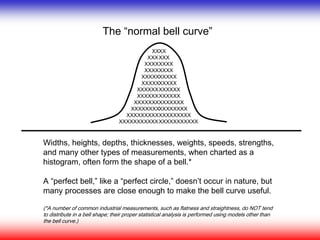

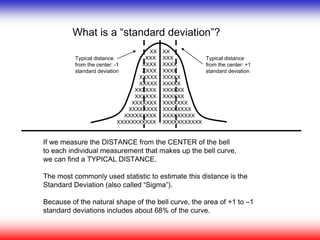

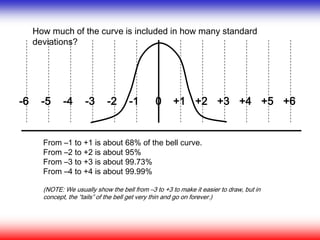

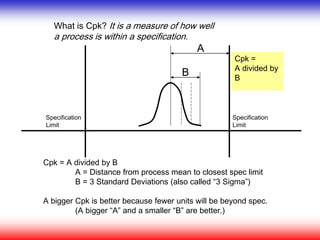

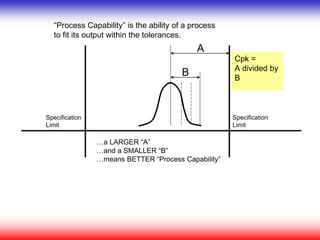

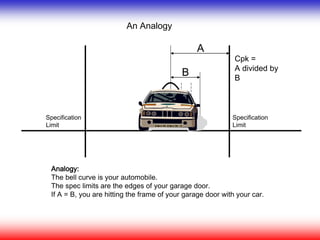

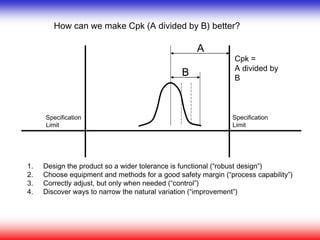

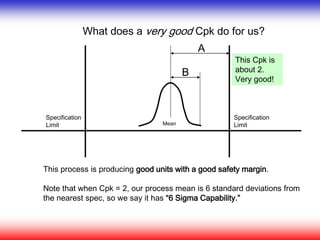

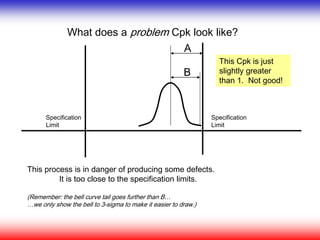

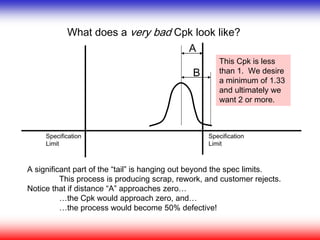

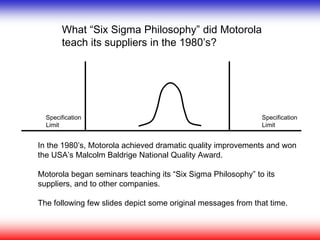

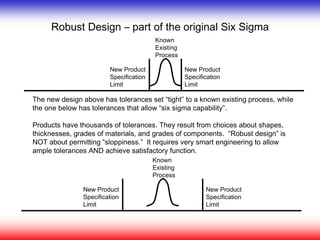

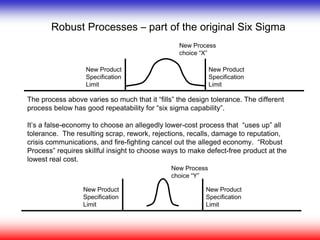

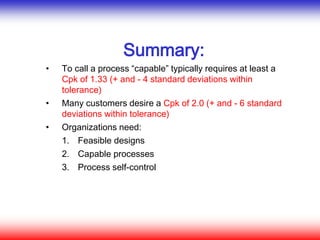

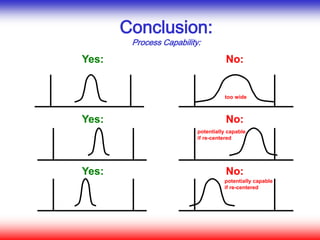

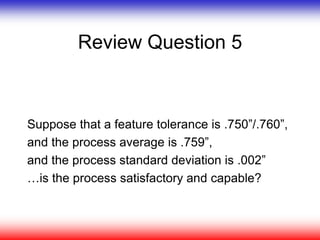

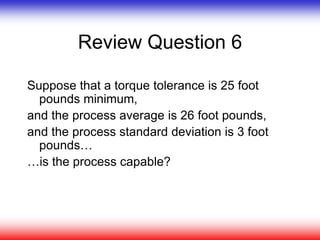

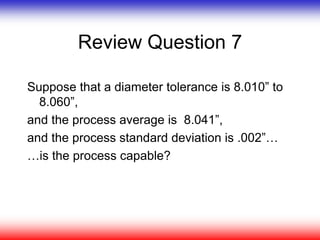

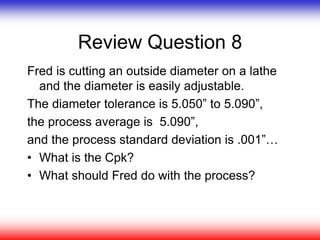

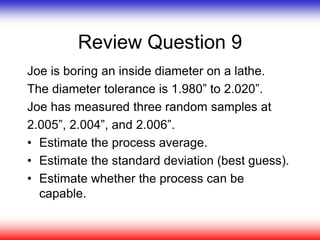

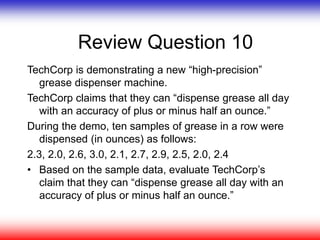

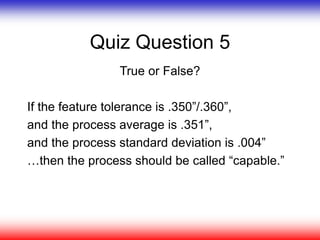

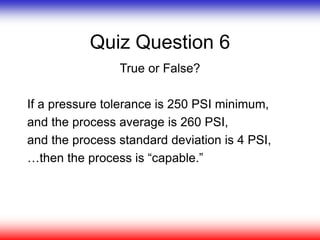

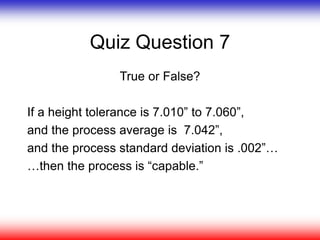

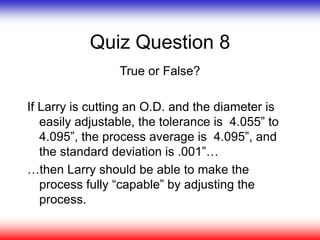

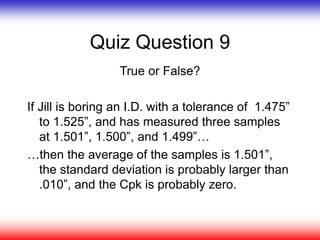

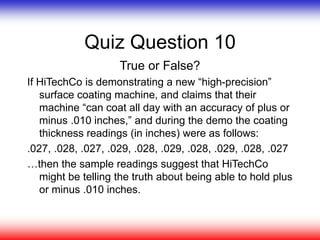

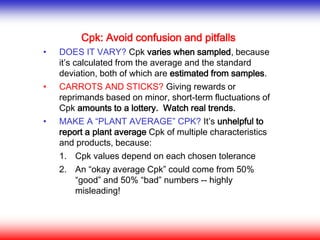

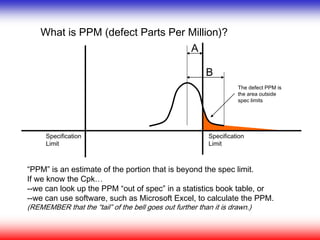

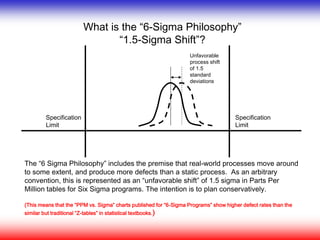

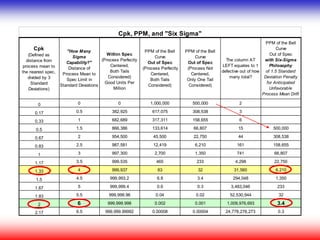

The document discusses process capability and how to evaluate whether a manufacturing process is capable of producing parts within its specified tolerances. It defines process capability as the ability of a process to make a feature within its tolerance. It describes how to calculate process averages and standard deviations from sample measurements and use those values to determine a process's Cpk value. A good process should have a Cpk of at least 1.33 but ideally 2 or more, indicating that the process mean is at least 6 standard deviations from the nearest specification limit. Graphs and examples are provided to illustrate capable versus incapable processes.