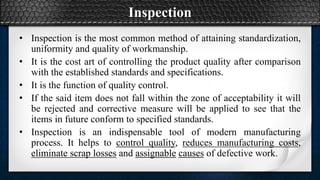

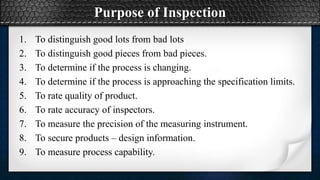

Inspection is used to ensure standardization, uniformity, and quality of manufactured products. It involves comparing products to established standards and specifications to determine if they are within an acceptable zone of quality. If not, the product is rejected and corrective actions are taken. Inspection helps control quality, reduce costs, and eliminate defects. There are two main methods: 100% inspection examines every single product but is costly, while sampling inspection tests a random sample of products and is cheaper but introduces sampling error. The objectives of inspection are to collect performance data, sort good and poor quality products, and establish reputation by protecting customers.