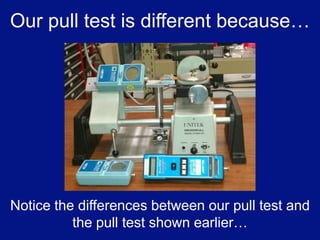

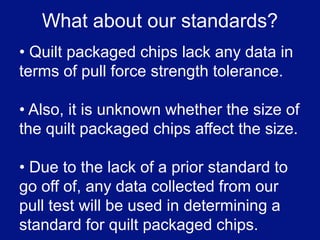

The document provides an overview of pull test systems used to assess the quality of wire bond interconnections in microchips, including definitions, methods, equipment, and standards. It distinguishes between destructive and nondestructive testing methods, detailing the specific equipment and setup used in their unique pull test for quilt packaged microchips, which diverges from traditional wire bond testing. The procedure for conducting the pull test and the standards applicable for quilt packaged chips are also outlined, noting that standards for these new designs have yet to be established.

![ReferencesKey Terms1 Gram-force (gf) = 9.80665 millinewtons(0.00980665Newtons) [4]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-18-320.jpg)

![1 pound (lb) = 4.4482 Newtons (N) [4]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-19-320.jpg)

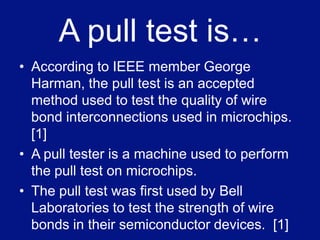

![A pull test is…According to IEEE member George Harman, the pull test is an accepted method used to test the quality of wire bond interconnections used in microchips. [1]A pull tester is a machine used to perform the pull test on microchips.The pull test was first used by Bell Laboratories to test the strength of wire bonds in their semiconductor devices. [1]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-21-320.jpg)

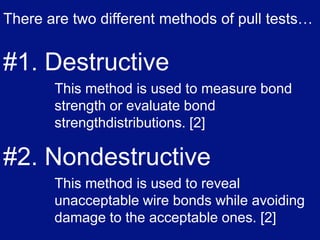

![There are two different methods of pull tests…#1. DestructiveThis method is used to measure bond strength or evaluate bond strengthdistributions. [2]#2. NondestructiveThis method is used to reveal unacceptable wire bonds while avoiding damage to the acceptable ones. [2]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-22-320.jpg)

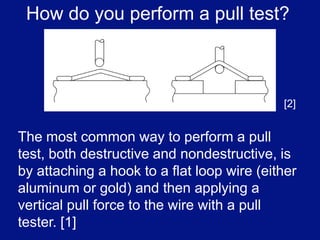

![How do you perform a pull test?[2]The most common way to perform a pull test, both destructive and nondestructive, is by attaching a hook to a flat loop wire (either aluminum or gold) and then applying a vertical pull force to the wire with a pull tester. [1]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-23-320.jpg)

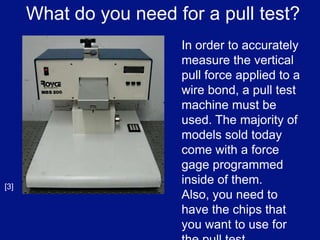

![What do you need for a pull test?In order to accurately measure the vertical pull force applied to a wire bond, a pull test machine must be used. The majority of models sold today come with a force gage programmed inside of them. Also, you need to have the chips that you want to use for the pull test.[3]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-24-320.jpg)

![StandardsThe standards for the destructive and nondestructive method aredescribed within MIL-STD-883 [2], a military document which has set the guidelines for the standards since the 1960s.Between the destructive method and nondestructive method, there are differences in the standards. But there are similarities as well…](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-25-320.jpg)

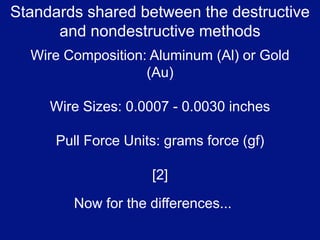

![Standards shared between the destructive and nondestructive methodsWire Composition: Aluminum (Al) or Gold (Au)Wire Sizes: 0.0007 - 0.0030 inches Pull Force Units: grams force (gf)[2]Now for the differences...](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-26-320.jpg)

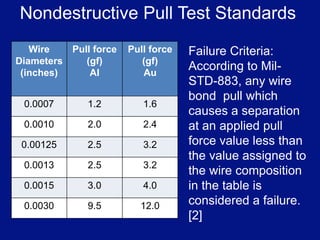

![Nondestructive Pull Test StandardsFailure Criteria: According to Mil-STD-883, any wire bond pull which causes a separation at an applied pull force value less than the value assigned to the wire composition in the table is considered a failure. [2]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-27-320.jpg)

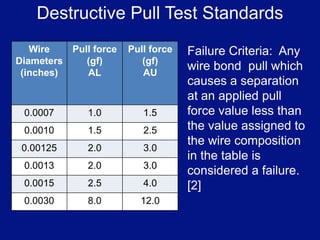

![Destructive Pull Test StandardsFailure Criteria: Any wire bond pull which causes a separation at an applied pull force value less than the value assigned to the wire composition in the table is considered a failure. [2]](https://image.slidesharecdn.com/pulltestpresentation-110706151233-phpapp01/85/Pull-Test-Presentation-28-320.jpg)