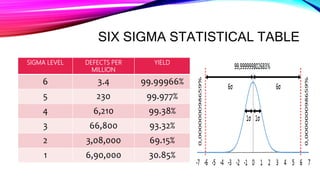

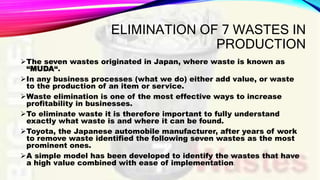

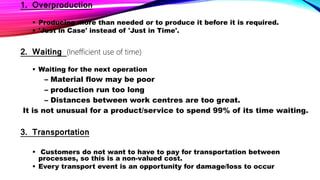

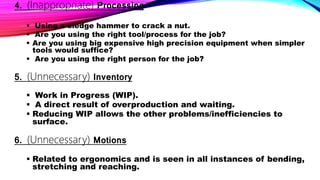

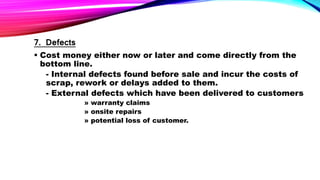

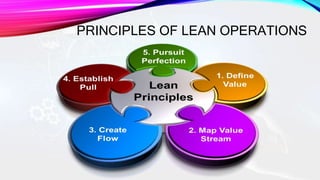

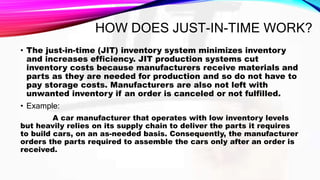

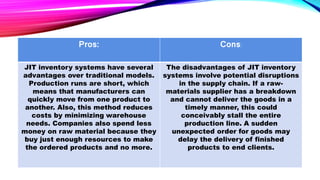

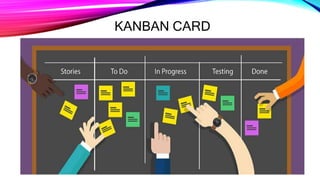

Six Sigma is a data-driven methodology for process improvement that aims to reduce defects. It was developed by Motorola in 1986 and uses statistical methods to identify and remove defects in manufacturing and business processes. The five phases of the Six Sigma methodology are Define, Measure, Analyze, Improve, and Control. Lean operations focus on eliminating waste to provide greater customer value with fewer resources. Key aspects of lean include just-in-time production and Kanban systems to minimize inventory levels and only produce what is needed.