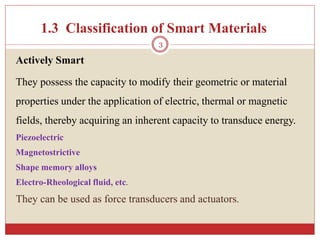

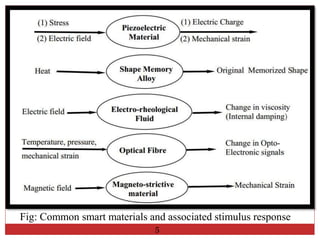

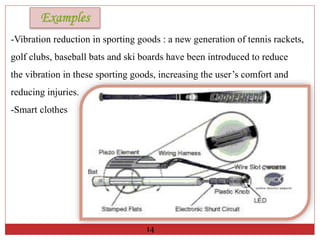

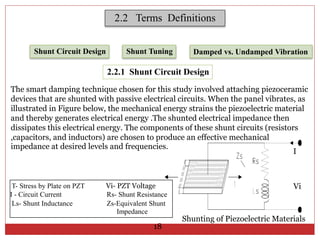

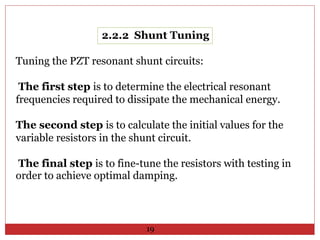

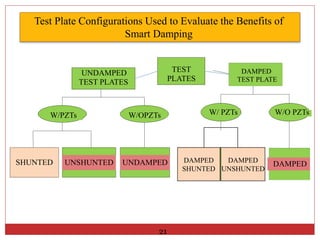

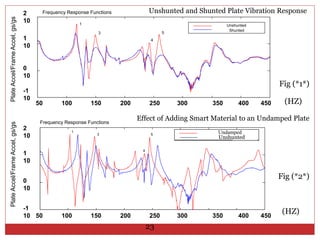

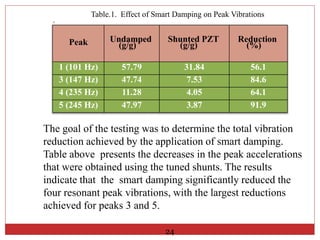

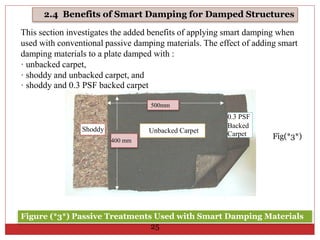

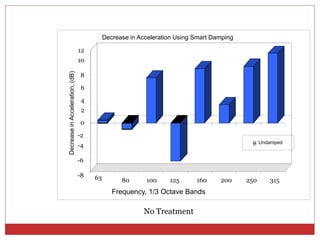

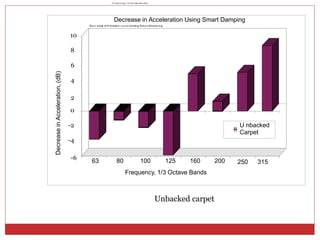

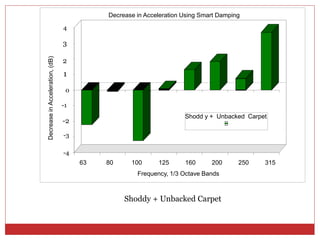

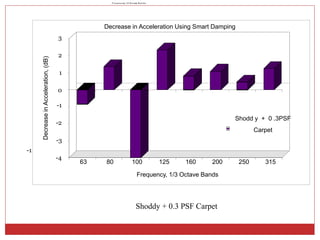

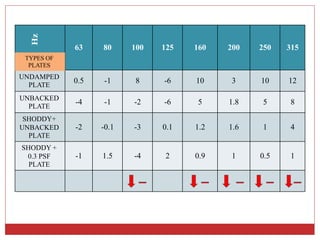

This document is a seminar report submitted by Diana Alkeflawi to the Mechanical Engineering Department at Erciyes University on smart materials for vibration reduction. The report discusses piezoelectric ceramics which are commonly used for active noise and vibration reduction in smart structures due to their ability to generate large forces and respond quickly. It compares vibration test results of a plate with and without smart damping and discusses the benefits of adding smart materials to existing damping materials.