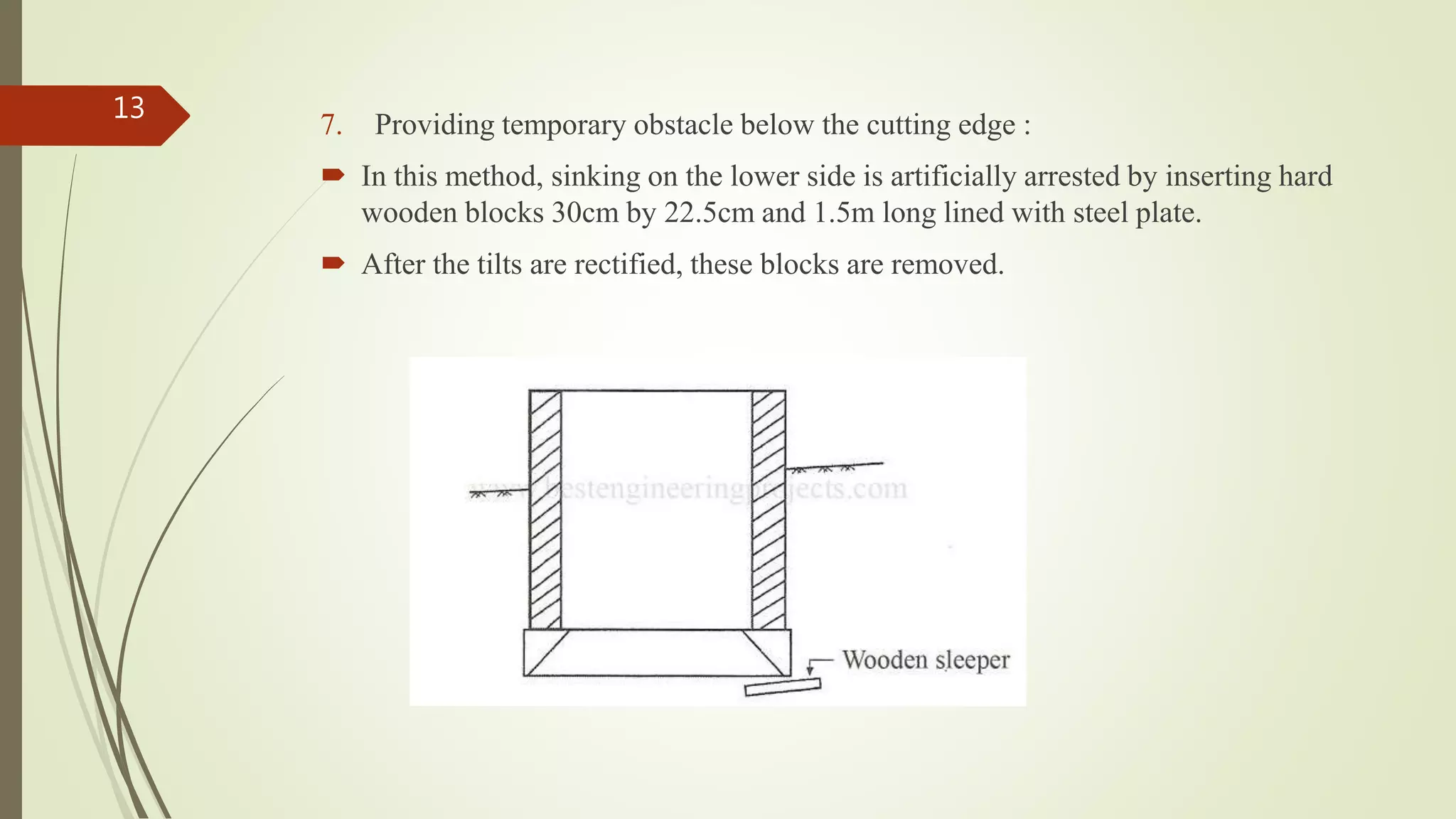

This document discusses the sinking, tilting, and diseases associated with caissons. It begins by defining caissons as watertight structures used in excavating foundations that become part of the substructure. Methods for sinking caissons include using air/water jets, blasting, loading with weight, and creating a sand island. Tilting can occur if a caisson sinks unevenly, and methods to correct tilting include controlling dredging, adding eccentric loads, using water jets, jacks, explosives, or depositing/excavating earth on different sides. Caisson disease, also called decompression sickness, can affect workers in compressed air and is caused by nitrogen bubbles forming in tissues upon rapid decomp