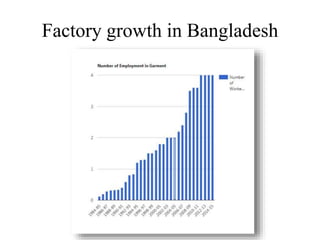

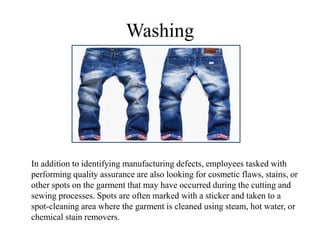

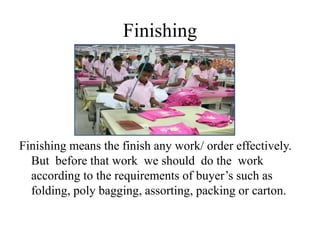

This presentation summarizes the garment manufacturing process in Bangladesh. It discusses the growth of Bangladesh's garment industry, which now accounts for 84% of the country's annual exports and $32.92 billion in revenue in 2017-2018. The presentation then outlines the typical sections in a garment factory: sample, cutting, sewing, washing, and finishing. It provides brief descriptions of the processes that occur in each section, such as fabric cutting to minimize waste and quality control checks during washing. In conclusion, the presentation notes that Bangladesh's garment industry has played a pioneering role in the country's economic development over the past 25 years.