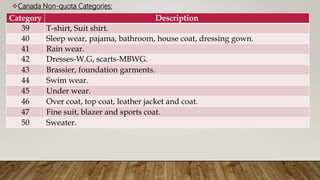

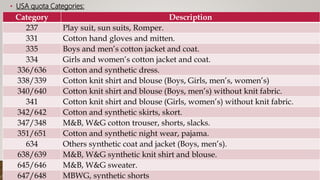

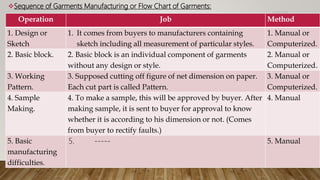

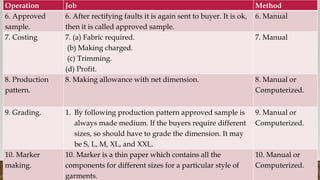

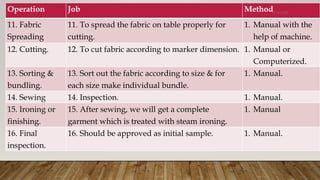

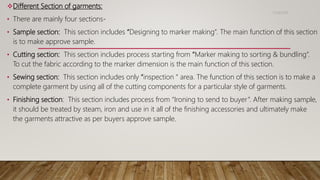

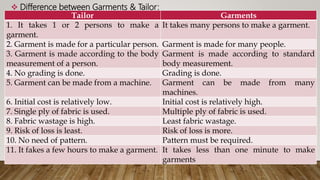

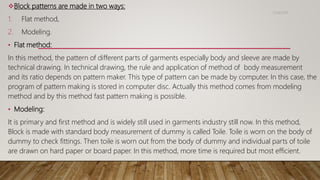

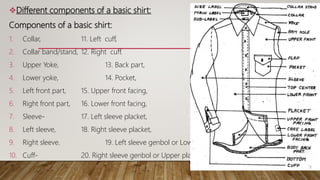

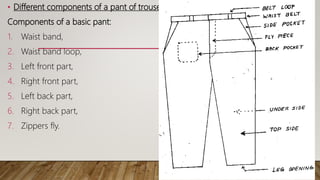

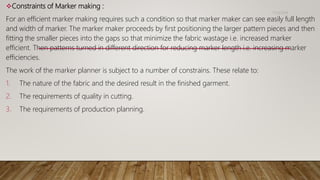

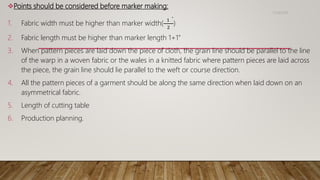

The document outlines the historical development and current state of the garments industry, particularly in Bangladesh, highlighting its growth from the establishment of the first garment factory in Paris in 1829 to becoming a significant exporter with a current count of around 3,700 factories. It discusses various methods of obtaining export orders, definitions of garment industry terminology, and the sequence of garment manufacturing processes. The document also describes different sections of garment production, compares tailoring with industrial garment manufacturing, and details components of basic clothing items.