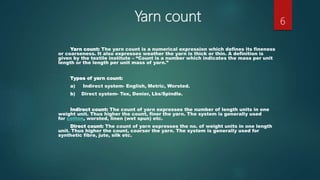

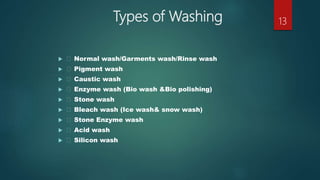

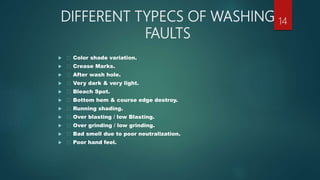

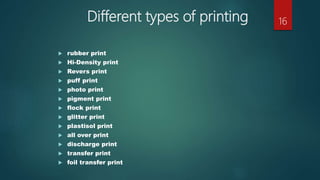

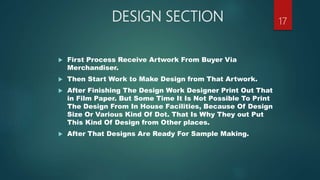

This document provides a summary of the author's industrial internship attachment at Bengal Hurricane Group, a knit garment manufacturing company in Bangladesh. Over three pages, the author outlines the major sections and processes within the company, including knitting, dyeing, washing, printing, garment production, quality control, finishing, and merchandising. For each section, the author describes the relevant processes, equipment, potential faults, and lessons learned. The overall summary provides insight into the full garment manufacturing process from fabric production to final product within a Bangladeshi export-oriented knitwear company.