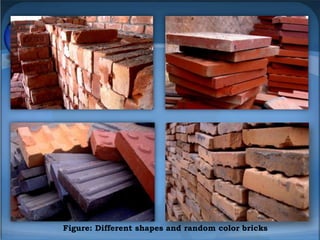

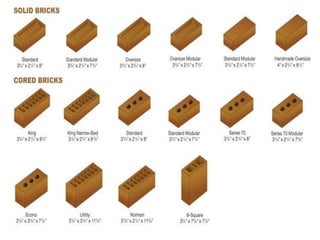

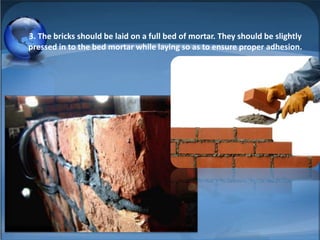

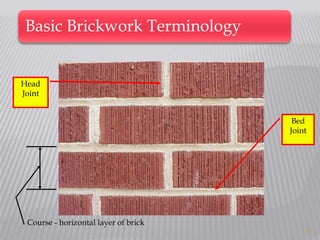

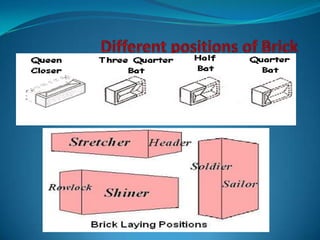

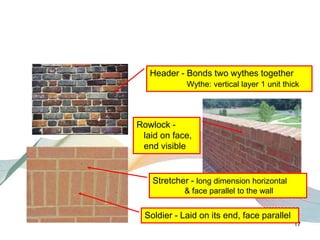

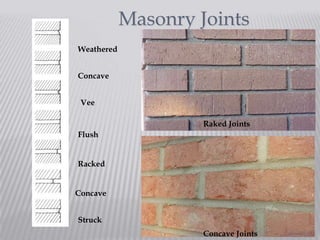

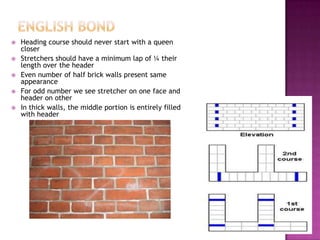

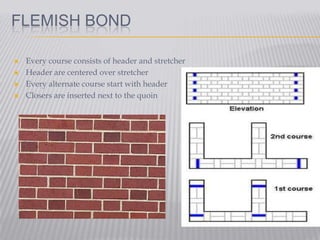

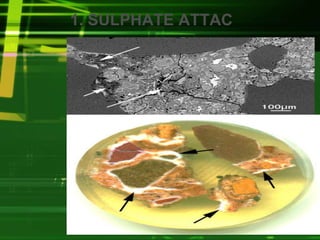

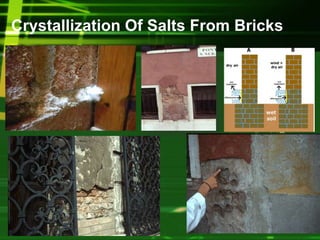

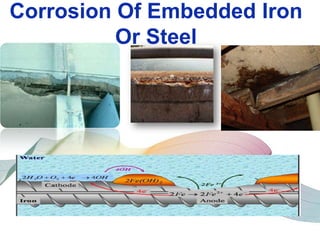

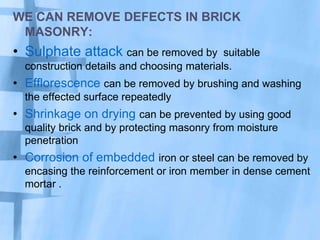

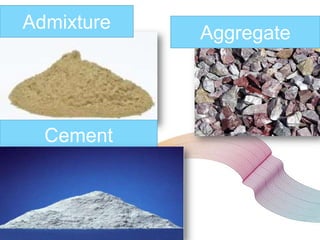

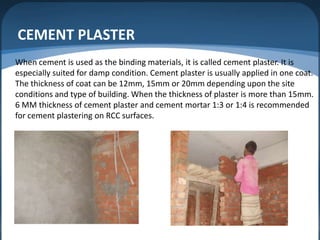

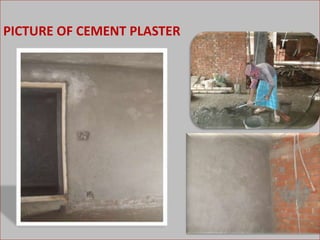

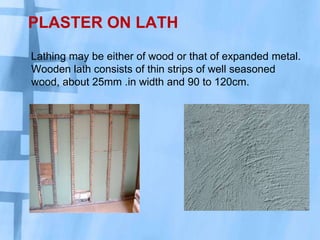

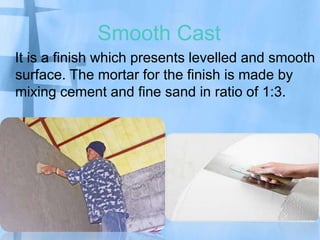

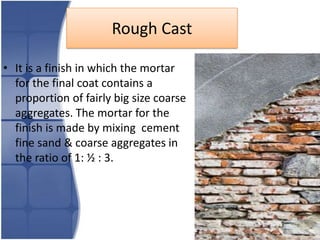

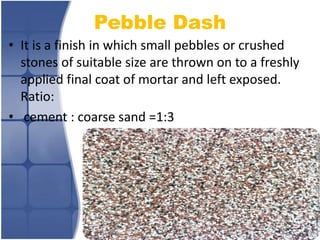

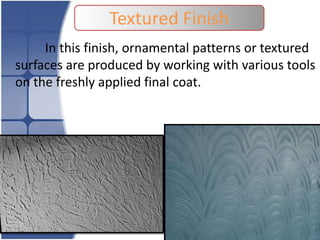

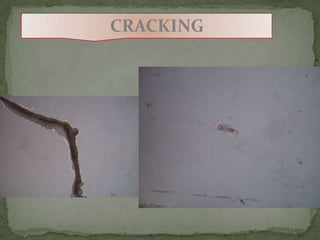

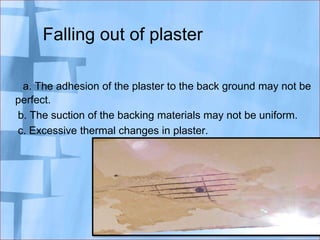

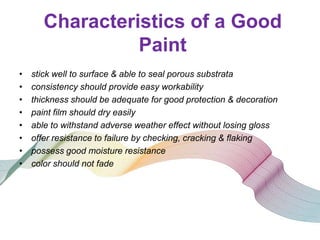

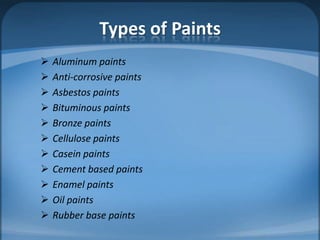

This document is the presentation slides for a group project on brick masonry, paint, and plastering. It includes an introduction slide with the group members' names. It then covers topics such as the definitions of masonry, brick masonry, types of bricks, bonding patterns, plastering materials and types, paint constituents, and defects and their remedies. Diagrams are provided to illustrate brickwork terminology, masonry joints, bond patterns, and plastering tools.