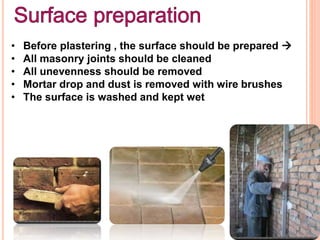

The document outlines the objectives and procedures of plastering, including the preparation of surfaces and the application of different types of plaster such as lime, cement, and gypsum plasters. It details the necessary coatings and their respective thicknesses along with precautions to avoid common issues like unevenness and cracking. Additionally, it introduces heat-resistant plaster designed for high-temperature applications.