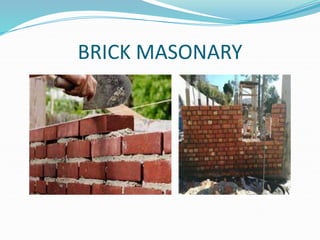

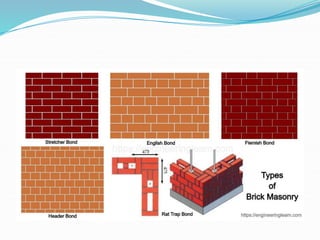

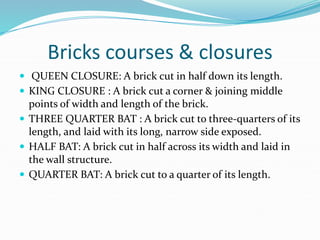

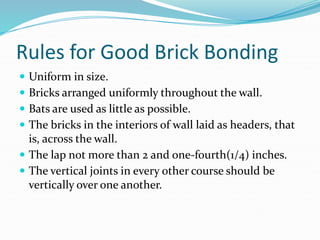

Brick masonry provides fire resistance, durability, and strength due to its homogeneous mass when bricks are laid in mortar. There are different types of bonds that provide varying strength, with English bond being the strongest. Bricks must meet quality standards like being uniformly shaped, emitting a clear ringing sound when struck, and having low water absorption. Proper tools and techniques are used to lay bricks in bonds with headers, stretchers, and closures to reinforce the wall structure. Brick masonry walls can be constructed using various bonds and have advantages of low cost and availability of materials.