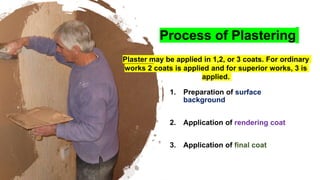

Plastering involves covering rough or uneven surfaces with plaster, a material made of lime or cement mixed with sand and water, to provide a smooth, durable, and protected surface. There are several types of plaster but commonly used ones include cement plaster and lime plaster. The plastering process generally involves three steps - preparing the surface, applying a rendering coat, and applying a final coat, with two or three coats used depending on the work. A good plaster should be economical, hard, adhere firmly, resist moisture, have good workability, and be applicable in all weather conditions.