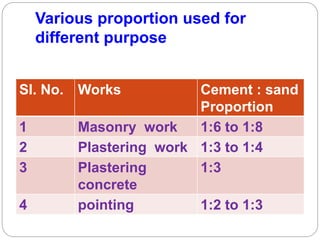

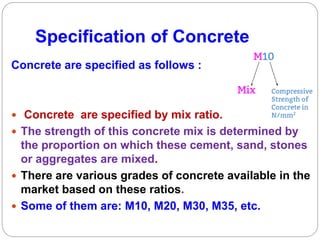

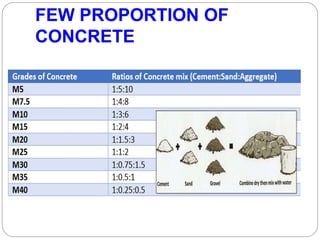

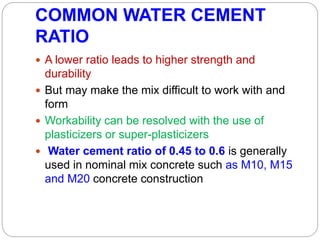

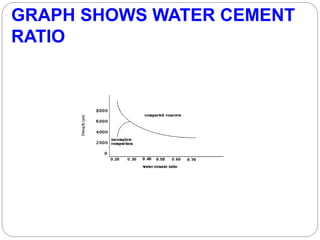

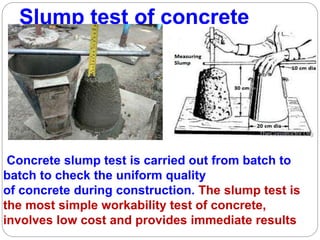

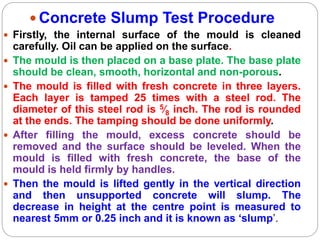

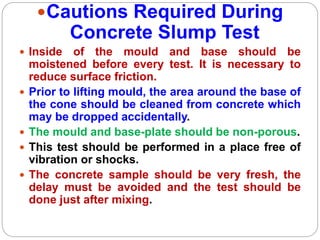

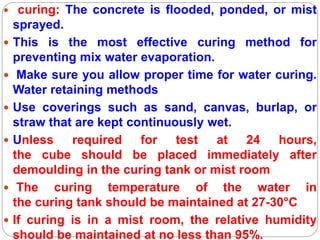

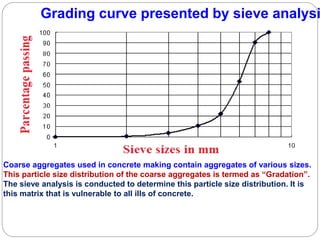

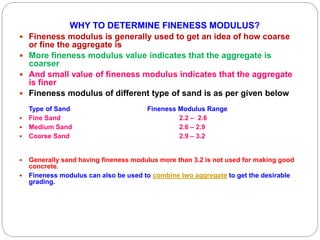

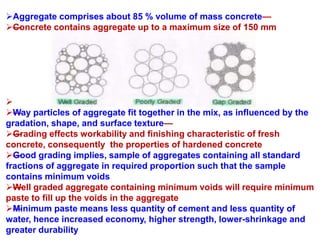

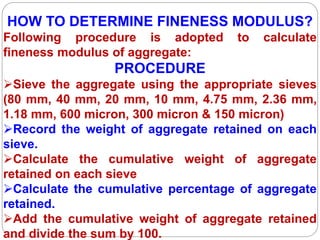

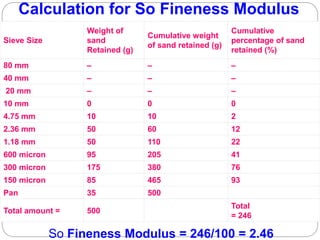

Cement mortar is a mixture used for masonry construction, such as between bricks. It binds the materials together and provides strength, stability, and durability to building structures. There are different types of mortars including lime, cement, surkhi, and mud mortars. Mortar hardens when it sets, forming an aggregate structure. Concrete is similar but contains coarse aggregates like gravel or stone, in addition to the binding materials, sand, and water. The document discusses the ingredients, mixing, curing, and testing of concrete, including its compressive strength and workability. Aggregates make up the bulk of a concrete mixture and affect its properties.