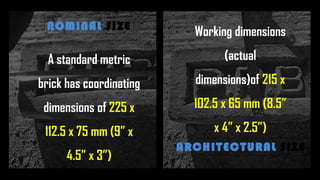

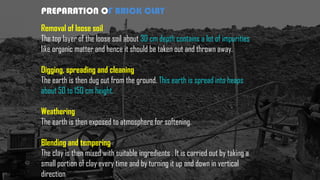

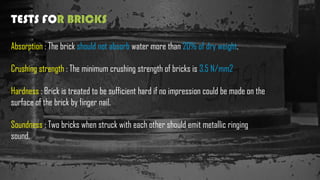

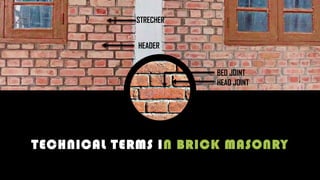

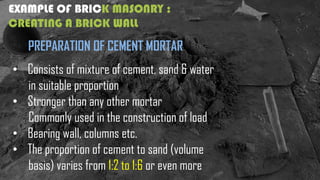

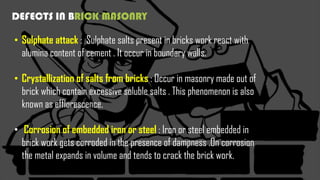

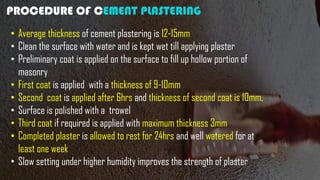

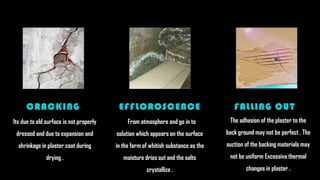

The document provides a comprehensive overview of bricks as a building material, detailing their classifications (burnt and machine-made) and specifications like water absorption and crushing strength. It also outlines the process of brick manufacturing, including clay preparation, moulding, drying, and burning, as well as various types of brick masonry and plastering techniques. Additionally, it discusses defects in brickwork and plastering, emphasizing the importance of proper techniques for durability and structural integrity.