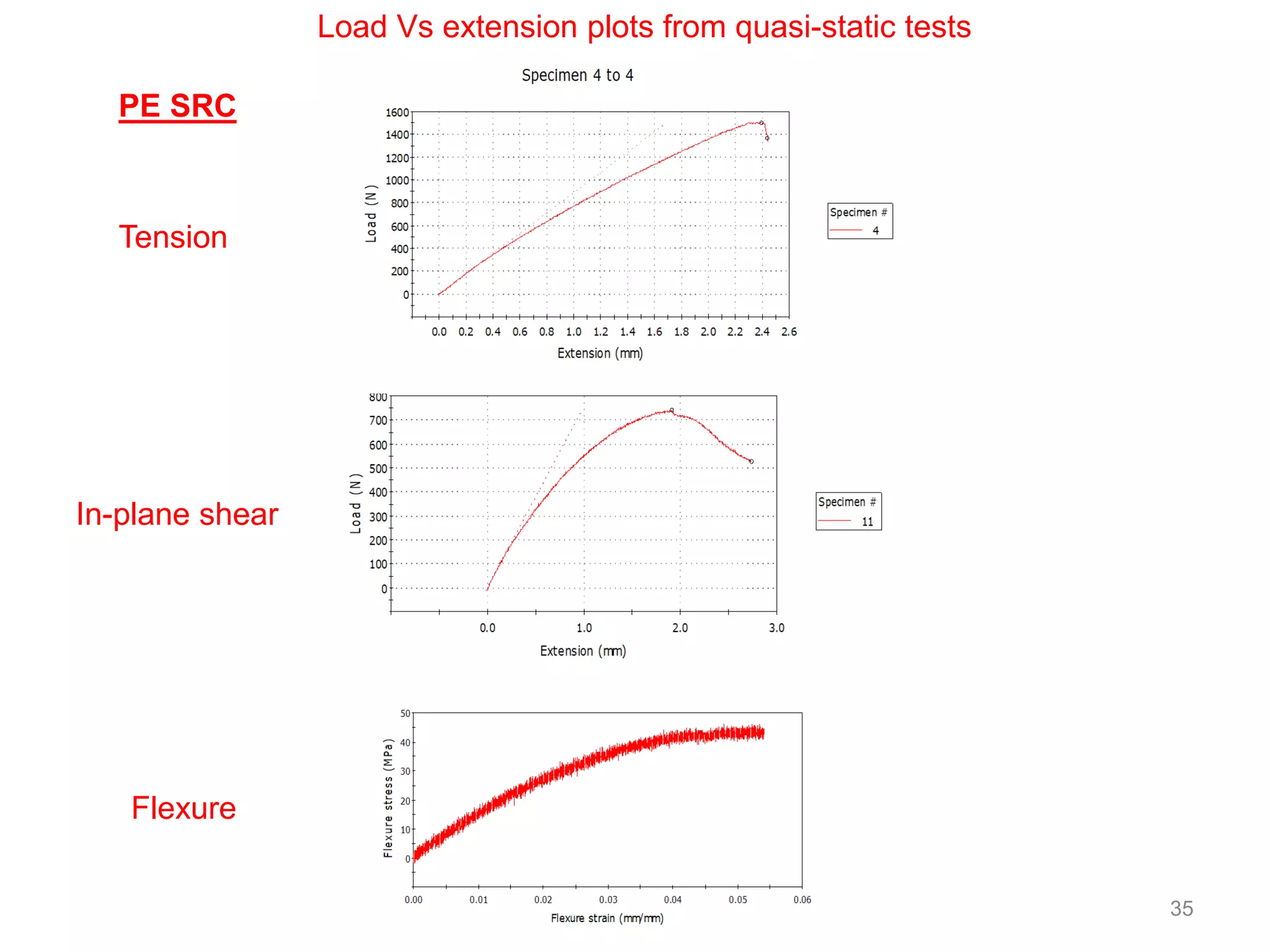

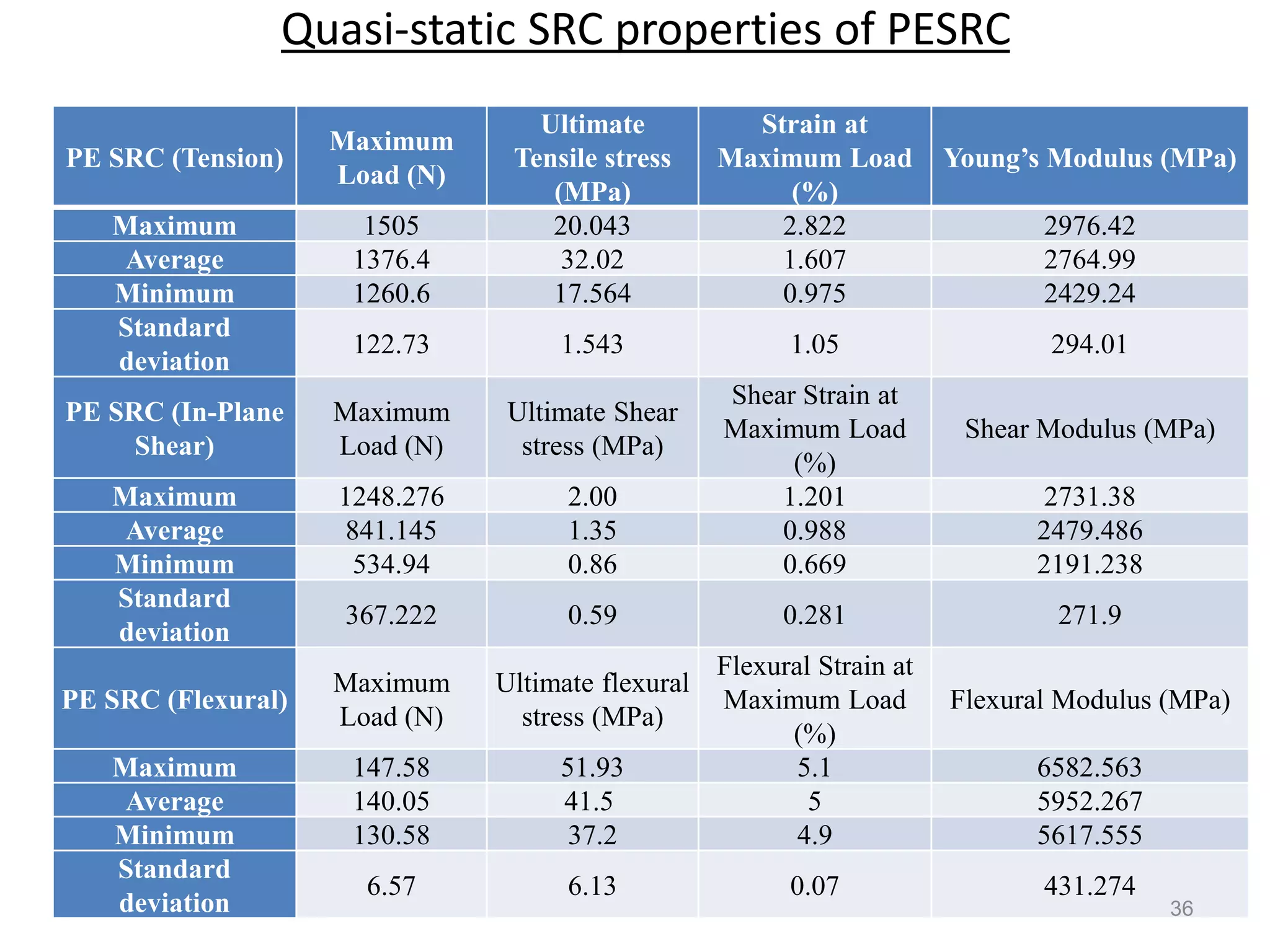

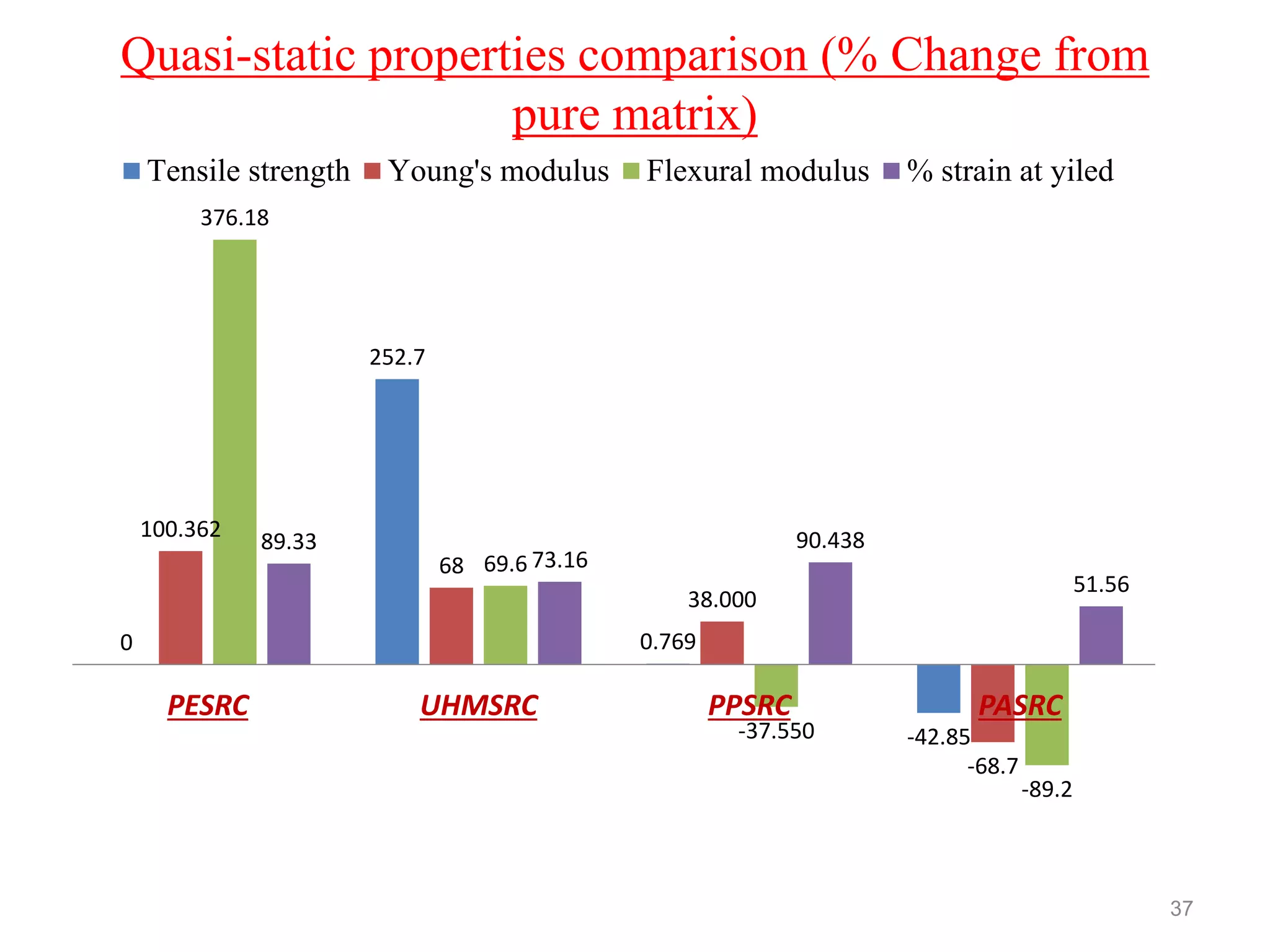

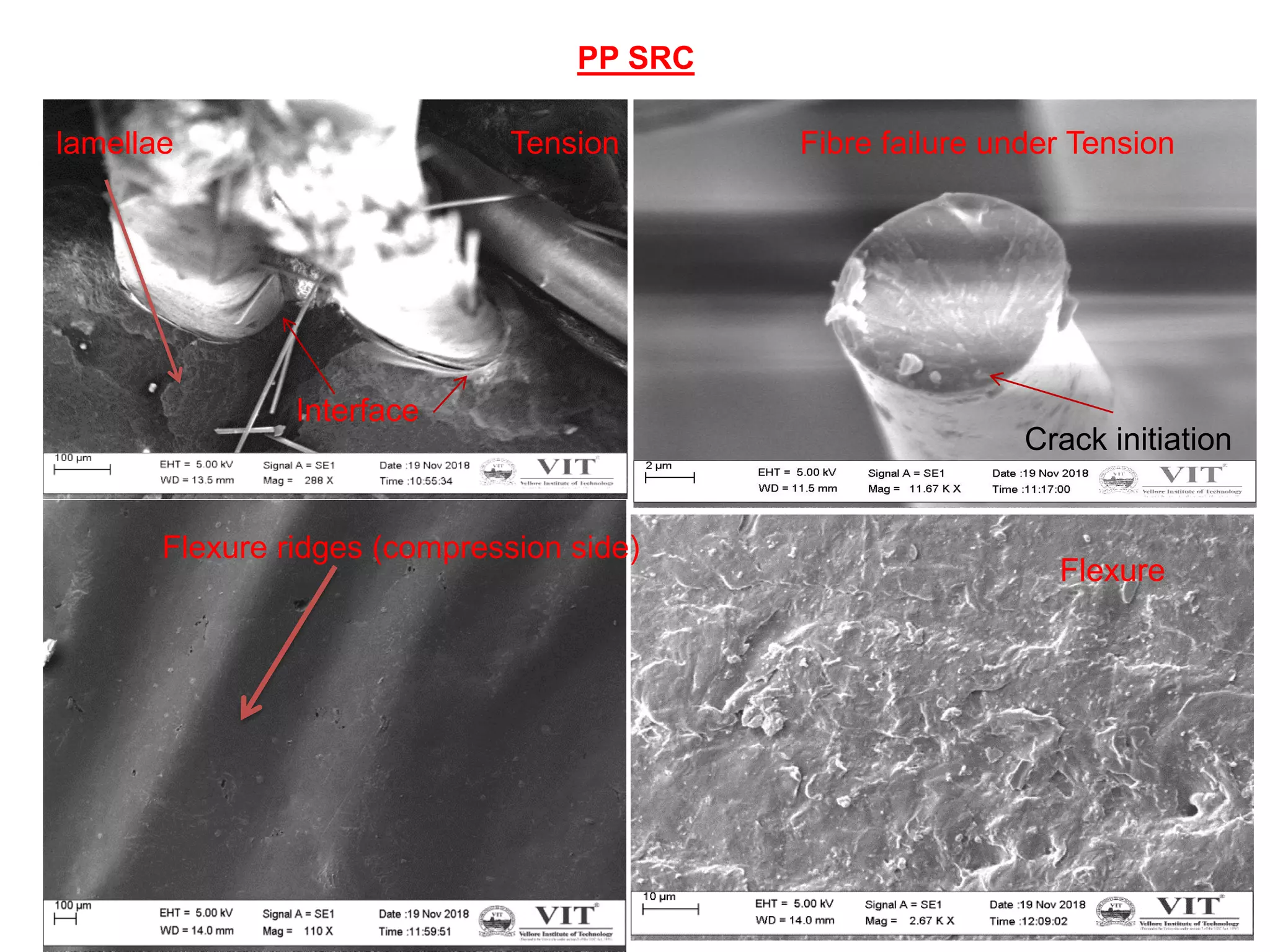

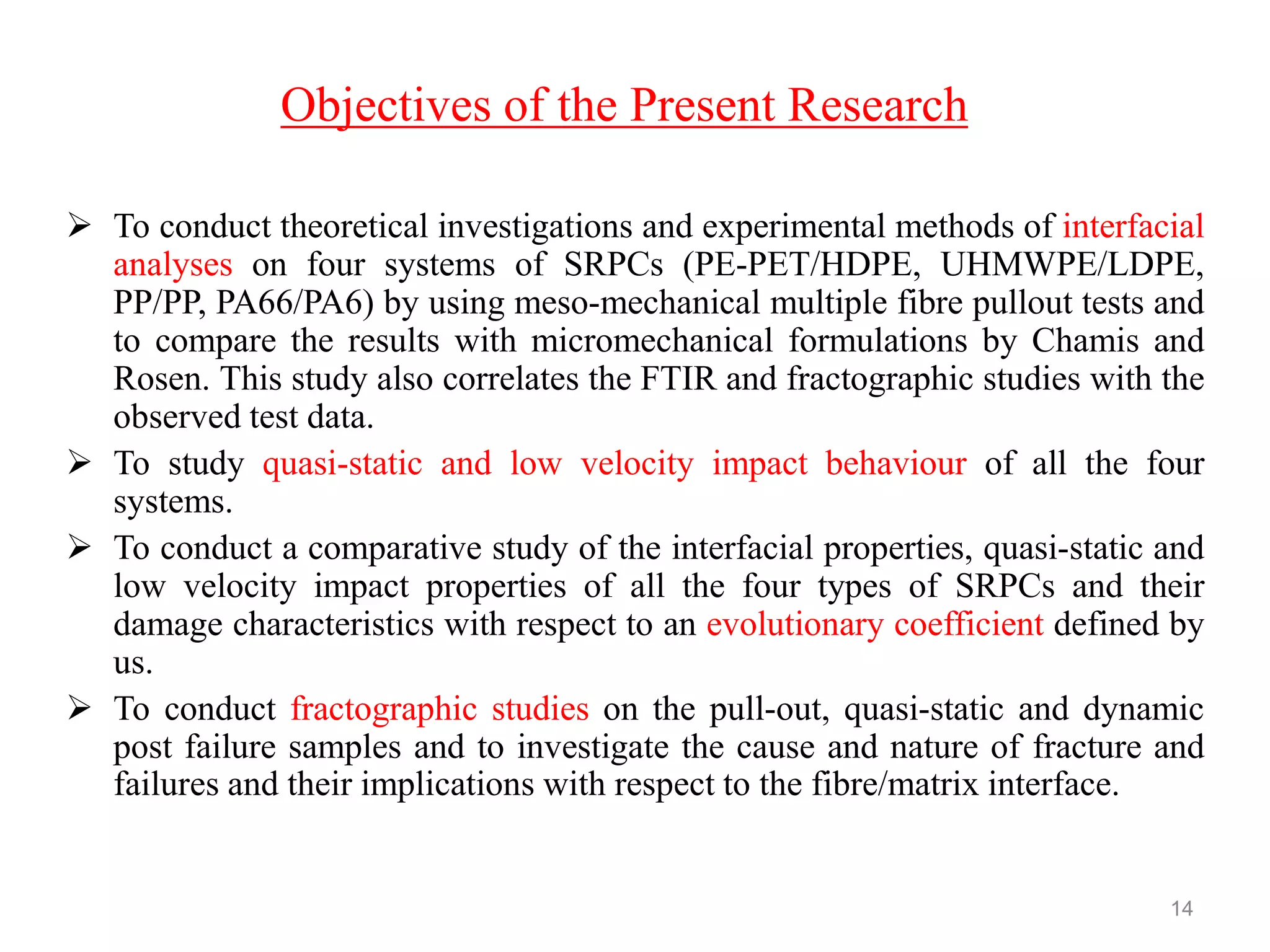

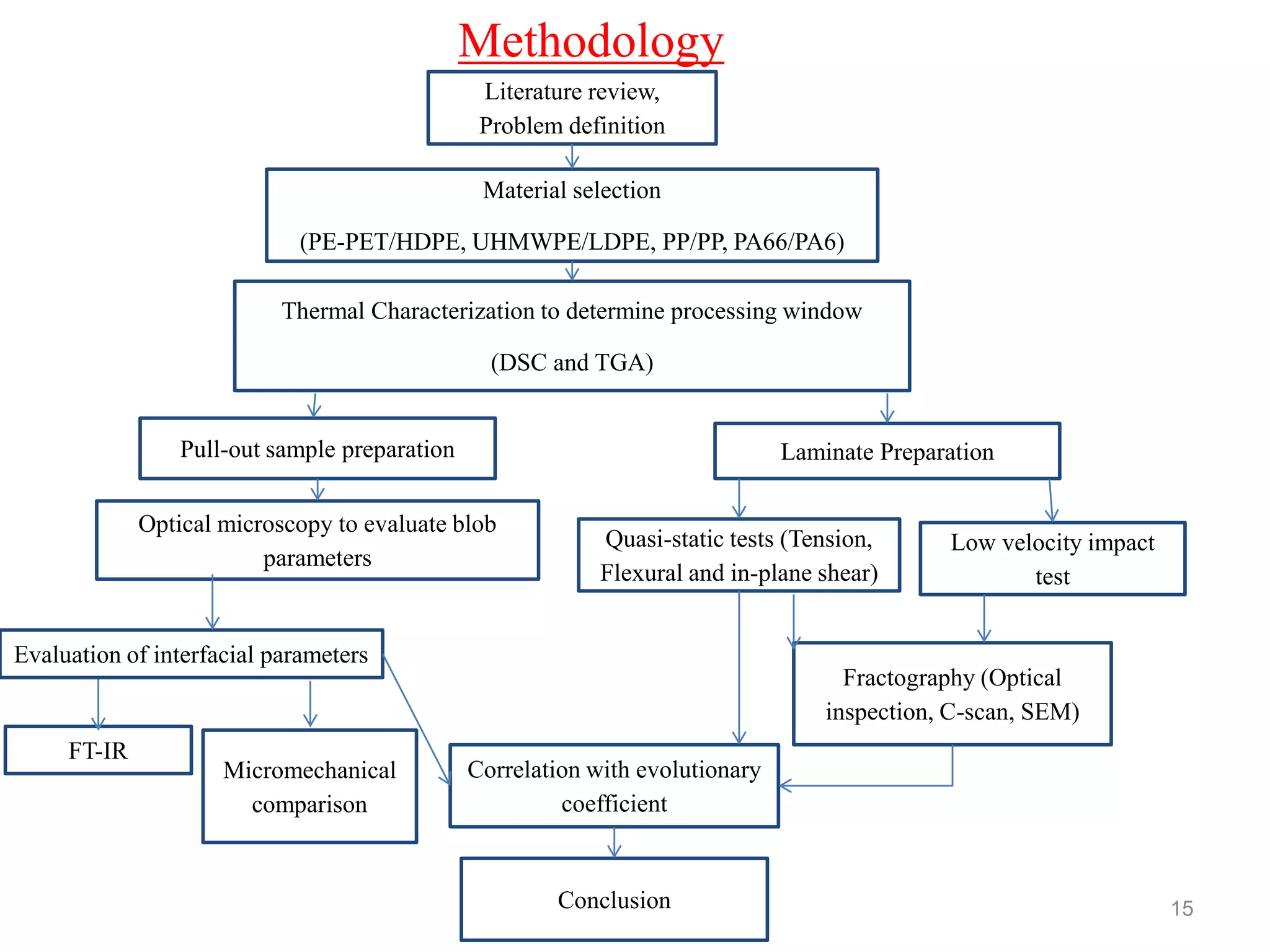

This document outlines the agenda and methodology for a research project on self-reinforced fibre polymer composites, with an emphasis on the fibre/matrix interface. The research will involve theoretical and experimental investigations of the interfacial properties, quasi-static properties, and low velocity impact properties of four types of self-reinforced polymer composites. Fractography and correlation studies will also be conducted. The goal is to better understand the relationship between interfacial properties, mechanical properties, and impact behavior, while addressing gaps in current literature regarding these composites. Thermal analysis, laminate preparation, mechanical testing, and microscopy techniques will be employed in the study.

![Micromechanical Formulations

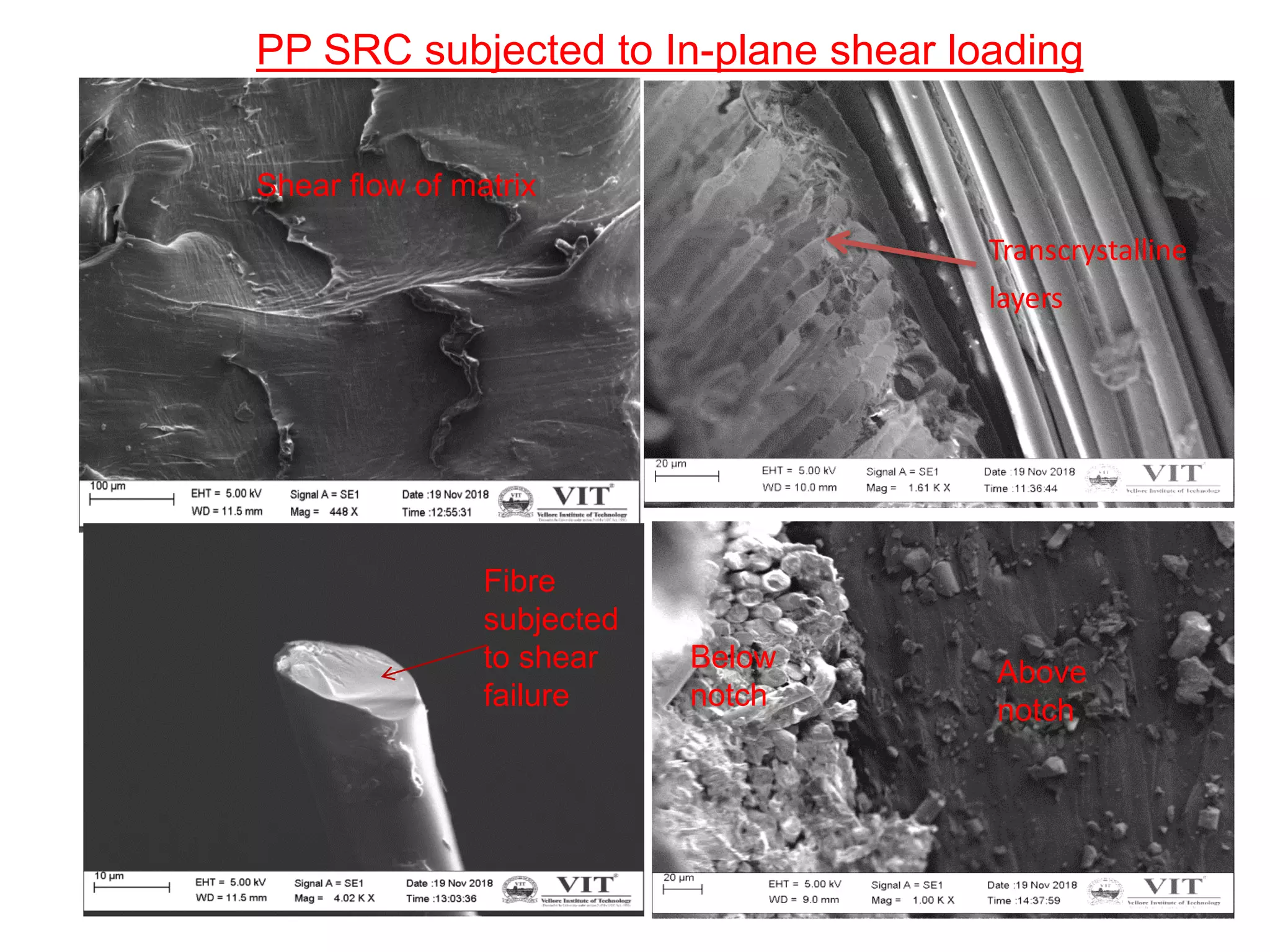

Inplane shear strength in MPa can be calculated by using

Chami’s prediction as

𝐹 = 𝜏 𝑚𝑢 𝐶𝑣[1+ (Vf-√Vf)(1- (Gm ⁄Gf)]

τmu is the matrix shear strength in MPa, Vf , is the fibre volume

fraction, and Gm and Gf are the matrix and fibre shear modulus in

GPa respectively. Cv is a factor representing the voids in the

system.

According to Rosen’s prediction, shear strength is modified by

introducing composite shear modulus and the shear strain and

the formulation is

τcomp = F tanh(γG12/F);

G12 is the composite shear modulus in GPa, γ, is the shear strain at

failure. (E J barbero;Design with Composite Materials;CRC Press) 21](https://image.slidesharecdn.com/finalvivafinal-200621181343/75/Preparation-and-characterization-of-self-reinforced-fibre-polymer-composites-with-emphasis-on-the-fibre-matrix-interface-21-2048.jpg)

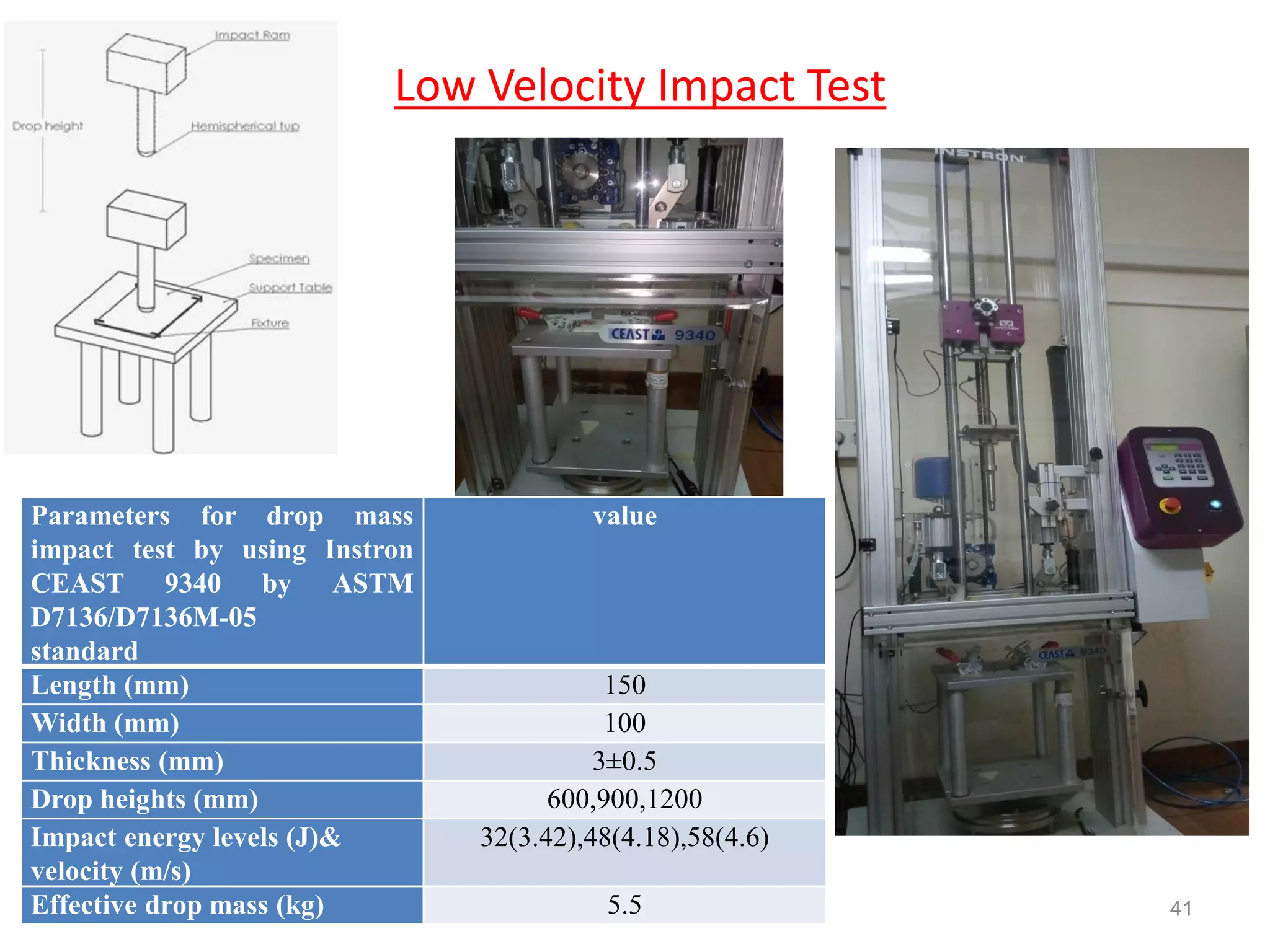

![Quasi Static Tests

Tensile Tests were conducted with standard

specimens. It was necessary to follow the procedure

set out in the standard D 3039 / D 3039 M – 95 A

proposed by ASTM.[30]

Flexural Test with ASTM D 790 M was followed

for three point bending test [31].

In-plane shear Test determines the adhesion

between the fibre and the matrix. Two notches are

made in each sample at 12.5 mm from the half-

length on either side .

34](https://image.slidesharecdn.com/finalvivafinal-200621181343/75/Preparation-and-characterization-of-self-reinforced-fibre-polymer-composites-with-emphasis-on-the-fibre-matrix-interface-34-2048.jpg)