This document presents a detailed finite element simulation analysis of orthogonal turning for three aluminum alloys (AA2024, AA6061, and AA7075) using the ABAQUS software, focusing on chip formation, stress, and temperature distribution during machining. It emphasizes the importance of thermal and mechanical properties in predicting tool wear and performance, and employs the Johnson-Cook damage model for analysis. Results indicate variations in machining efficiency based on material behavior under dynamic conditions, with key metrics evaluated and compared to experimental investigations.

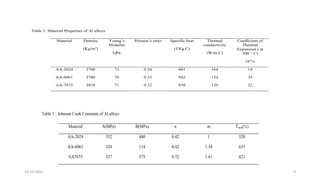

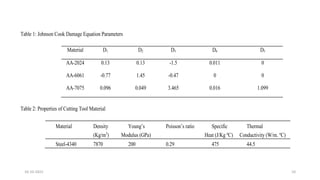

![John-Cook Plasticity Model

The equations and constants that Johnson-Cook derived for strain rate in the machining are published in previous

papers by noteworthy researchers [13,14,15,16,18].

------------- (1)

-------------- (2)

Where

Equivalent von mises flow stress in MPa.

= Strain at fracture

= Equivalent plastic strain

n = Strain hardening index

= equivalent plastic strain rate in s-1

= Initial dimensionless plastic strain rate

ё = Ratio of Equivalent plastic strain rate and initial dimensionless plastic strain rate

σ*

= Ratio of pressure to effective stress

Tmelt = Melt temperature in Degree Celsius

Troom = Work piece transition temperature in Degree Celsius.

m = An index or material constant determined from known temperatures and strain rates.

A, B, C, D1, D2, D3, D4, D5 are constants. Here for a time-step and path dependent damage analysis , the constant

C is not required to be used.

16-10-2022 7](https://image.slidesharecdn.com/modellingsimulationandfiniteelementanalysesof-221016155932-62aa1218/85/Modelling-Simulation-and-Finite-Element-Analyses-of-pptx-7-320.jpg)

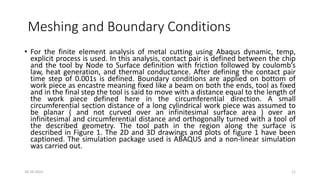

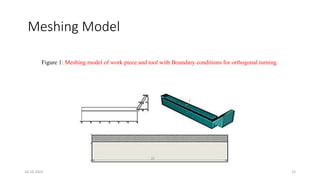

![Assumptions….

• Work Piece was not rotated and is defined as prismatic in shape. The Machining Parameters were

• Feed (f) = 20 m/s

• Cutting time (t) = 1 milli second

• Depth of cut (d) = 1 mm

• Metal Removal Rate = [Area of Work piece –Area of Cutting Portion] * Feed

• = [8mm2 - 2mm2] *20*103 mm/s

• = 12*104 mm3/s

• Explicit dynamics analysis is adapted here, the part above the work piece only is meshed with explicit elements. Heat generation

by friction is assumed. The thermal heat generation is assumed to be adiabatic under the present conditions where millisecond

events are recorded. The high plastic strain rate is a manifestation of the adiabatic heat rise due to turning that causes ductility.

High feed and a depth of cut on the higher side were assumed for the simulation which is with in the upper limit normally used for

aluminium turning. The heat generation and cutting forces are expected to be on the higher side compared to some of the

simulations that have not used the J-C model for the temperature and stresses observed. Not withstanding the above said

argument, some investigators have optimized the process parameters in the, CNC turning of Aluminium alloys using hybrid RSM

cum TLBO approach and also probed into a multi-objective optimization of cutting conditions when turning Aluminium Alloys

1350-O and 7075-T6 grades using genetic algorithm . The two investigations cited here have optimized the turning operation

specifically for an alloy mentioned and not for the alloys under investigation here that undergo orthogonal turning which is known

to produce higher temperatures and cutting forces due to the nature of tool contact with work piece.

16-10-2022 14](https://image.slidesharecdn.com/modellingsimulationandfiniteelementanalysesof-221016155932-62aa1218/85/Modelling-Simulation-and-Finite-Element-Analyses-of-pptx-14-320.jpg)