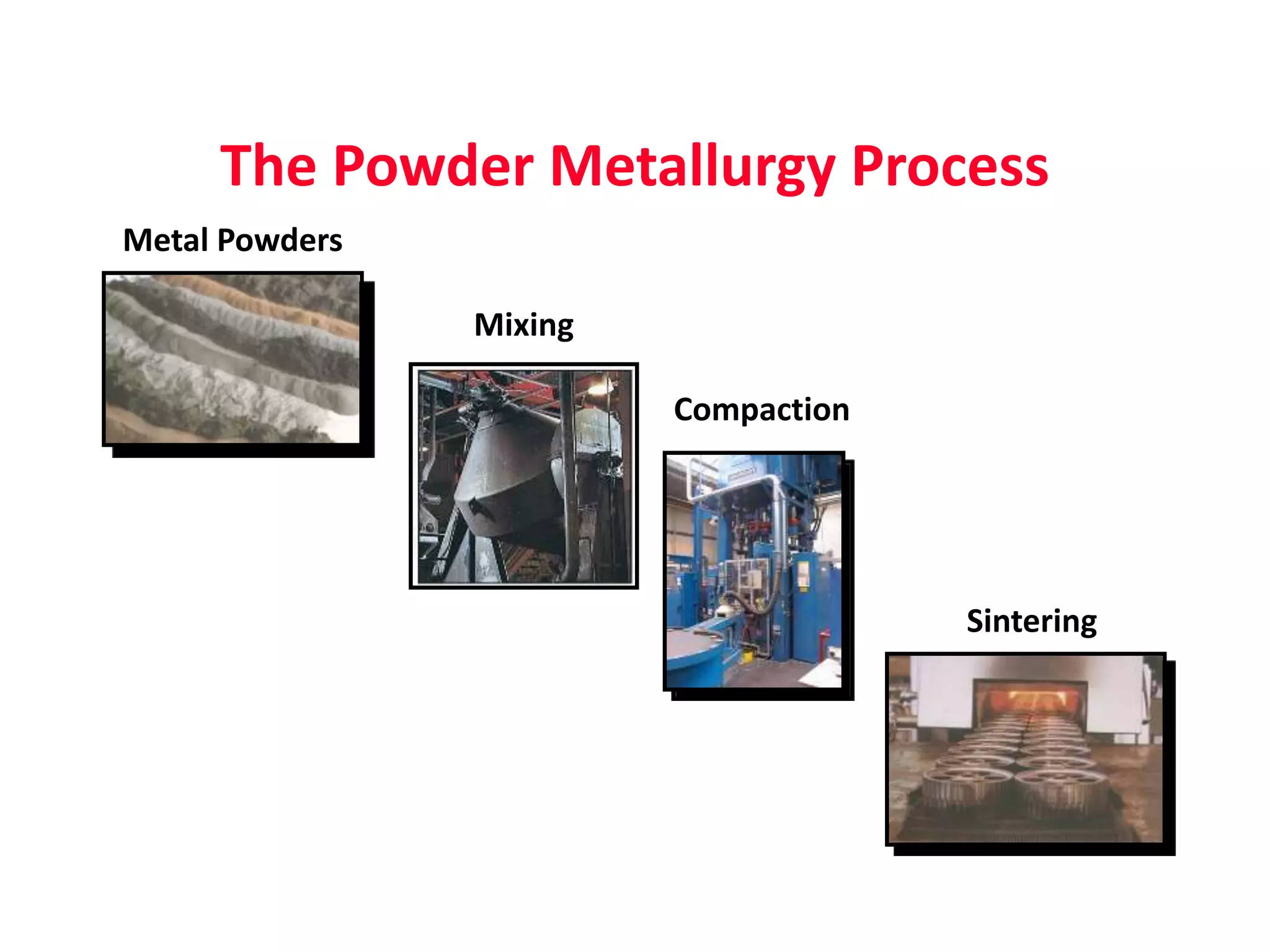

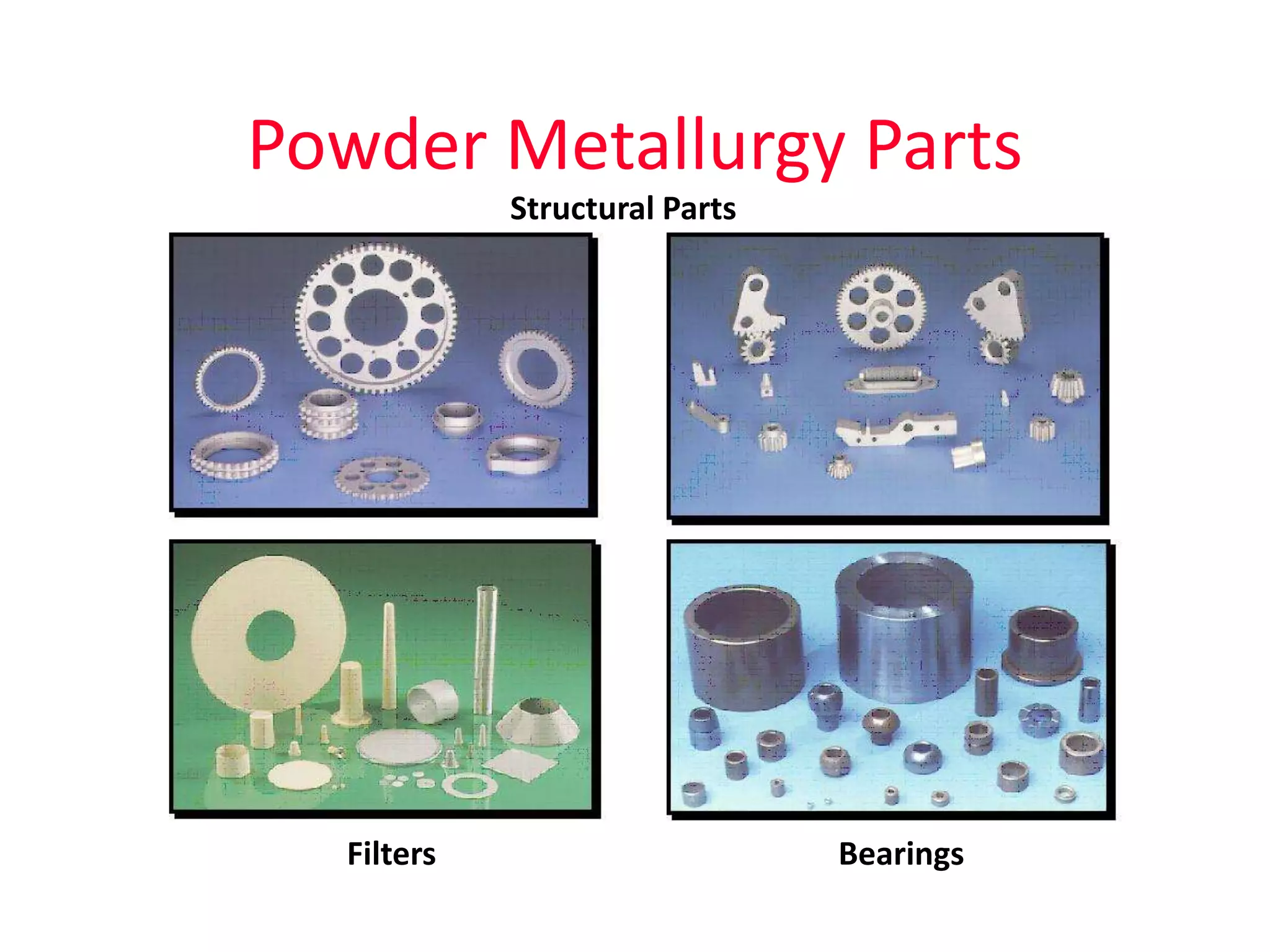

Powder metallurgy involves compacting metal powders and sintering them to produce dense materials and components. The process allows fabrication of metals that are difficult to melt and cast. Parts produced through powder metallurgy can achieve close dimensional tolerances. The process involves mixing metal powders, compacting them into a green compact, sintering to bond the particles through diffusion, and optional secondary operations like machining. Applications include automotive components, cutting tools, batteries, and filters. Standards organizations establish guidelines for powder metallurgy.