Embed presentation

Downloaded 34 times

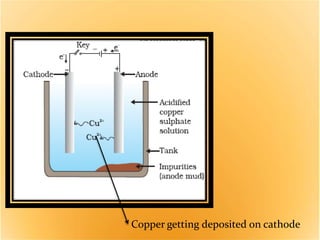

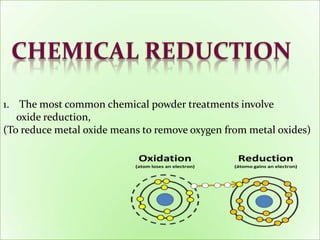

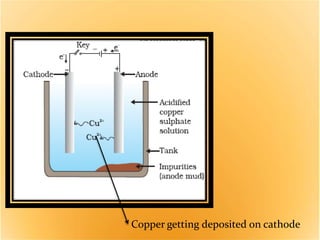

Chemical reduction is a common process for producing metal powders that involves reducing metal oxides, carbonates, or nitrates at temperatures below the metal's melting point. This results in a reduced product that is then crushed and ground into a powder. Some advantages are that it is simple, flexible, and an only method for producing powders of metals like molybdenum and tungsten. Electrolytic processing involves electrolysis where a metal deposits as a powder on cathode plates in an electrolytic tank. The deposited powder is then scraped off and pulverized. Decomposition involves breaking down organic substances into simpler forms, and is used for producing iron and nickel powders where decomposition sintering requires less temperature than